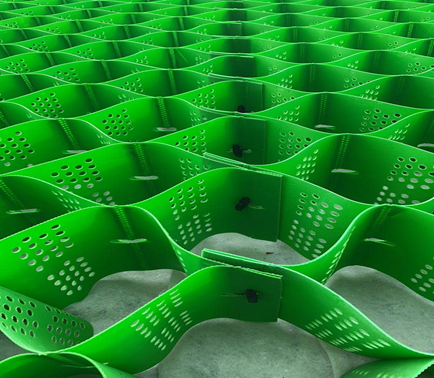

Lianyi polyester uniaxial geogrids are a popular choice for reinforcing retaining walls due to their high tensile strength and durability. These geogrids are designed to provide reinforcement in one principal direction, which makes them ideal for applications where the primary stresses are aligned in a single direction, such as in retaining wall structures. Here’s a comprehensive overview of their application and benefits:

Key Features of Polyester Uniaxial Geogrids

High Tensile Strength: Polyester geogrids offer significant tensile strength, which is crucial for reinforcing soil in retaining wall applications. They help to distribute loads effectively and increase the stability of the structure.

Chemical and Biological Resistance: Polyester geogrids are resistant to chemical degradation and biological factors. This makes them suitable for long-term use in various environmental conditions.

Durability: These geogrids are designed to withstand harsh environmental conditions, including UV exposure, making them a durable option for long-term applications.

Creep Resistance: Polyester has excellent resistance to creep, meaning it can maintain its structural integrity over time even under constant load.

Applications in Retaining Wall Reinforcement

Soil Reinforcement: The primary use of polyester uniaxial geogrids in retaining walls is to reinforce the soil. They help in maintaining the stability of the soil by preventing lateral movement and distributing loads.

Slope Stabilization: In addition to retaining walls, these geogrids are also used in slope stabilization projects. They help to stabilize slopes and prevent landslides by reinforcing the soil and improving its load-bearing capacity.

Construction of Steep Slopes and Embankments: For constructing steep slopes and embankments, polyester uniaxial geogrids provide the necessary support to ensure stability and prevent erosion.

Installation Process

Excavation: The area where the retaining wall is to be built is excavated to the required depth.

Placement of Geogrid: The polyester uniaxial geogrid is laid out horizontally over the excavated area. It is typically placed in layers, with each layer being compacted before the next layer is added.

Backfilling: Soil is backfilled over the geogrid in layers, with each layer being compacted. The process is repeated until the desired height of the retaining wall is achieved.

Facing: A facing system, which could be made of concrete, stone, or other materials, is often installed in front of the geogrid-reinforced soil to provide a finished look and additional structural integrity.

Benefits of Using Polyester Uniaxial Geogrids

Improved Structural Integrity: By reinforcing the soil, geogrids improve the overall structural integrity and longevity of the retaining wall.

Cost-Effective: They are a cost-effective solution compared to traditional retaining wall reinforcement methods.

Easy Installation: The installation process is relatively straightforward and can be completed with standard construction equipment.

Environmental Sustainability: Geogrids allow for the use of locally available materials, reducing the need for imported fill and minimizing environmental impact.

Conclusion

Polyester uniaxial geogrids are a reliable and efficient solution for reinforcing retaining walls. Their high tensile strength, durability, and resistance to environmental factors make them suitable for a wide range of applications, ensuring the stability and longevity of retaining wall structures. When properly installed, these geogrids can significantly enhance the performance and safety of retaining walls, making them an excellent choice for civil engineering and construction projects.