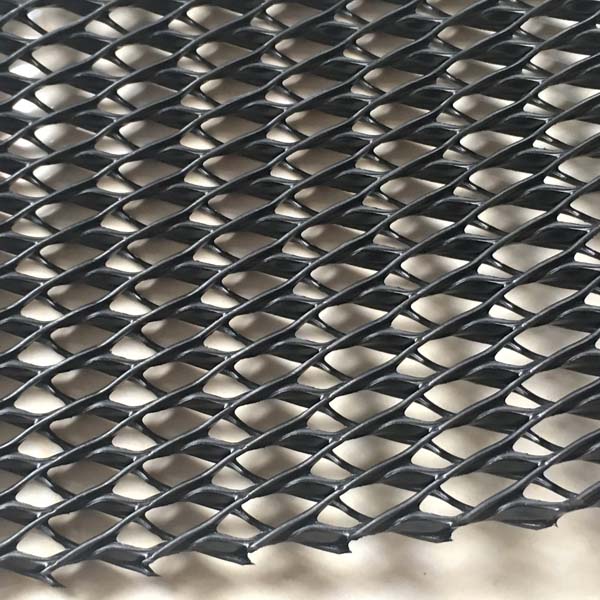

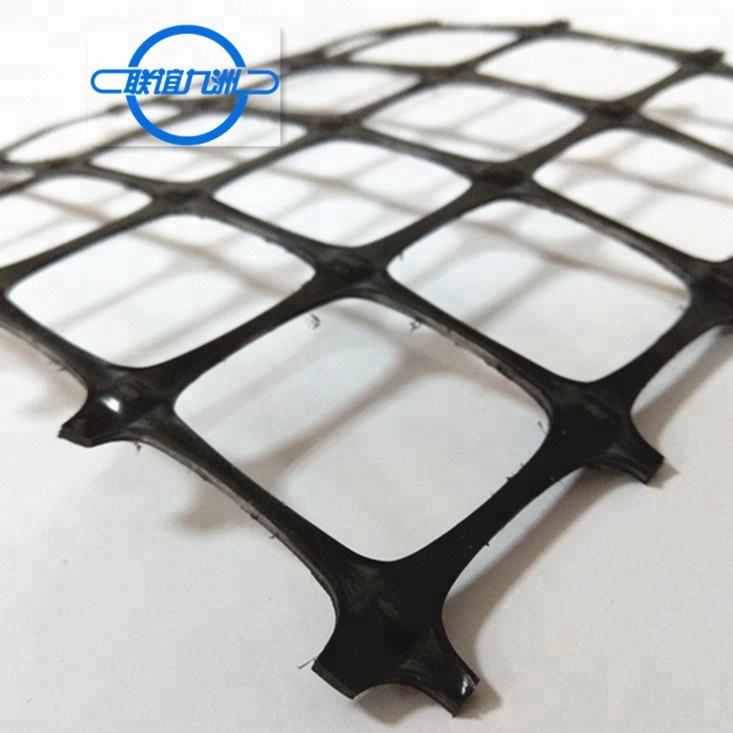

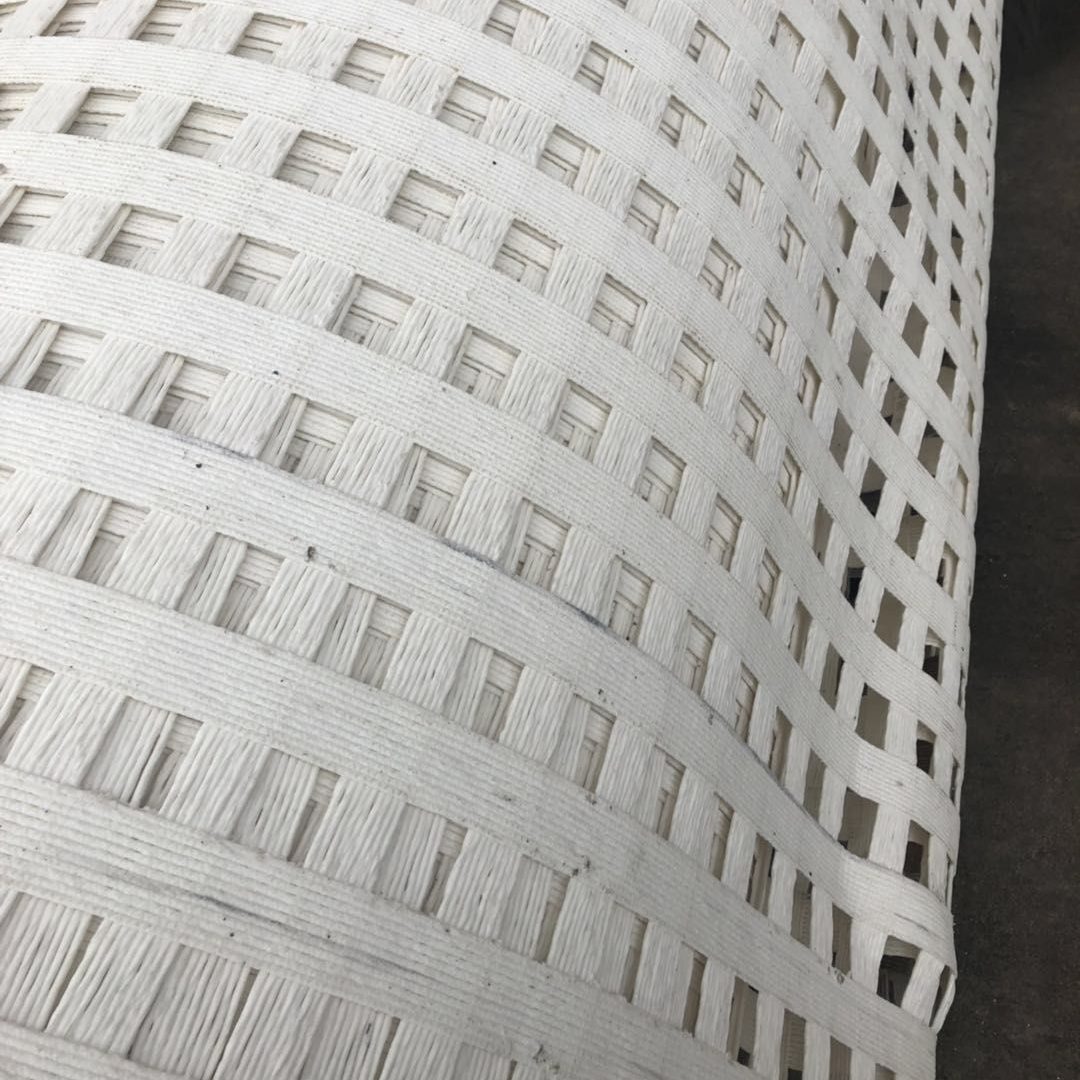

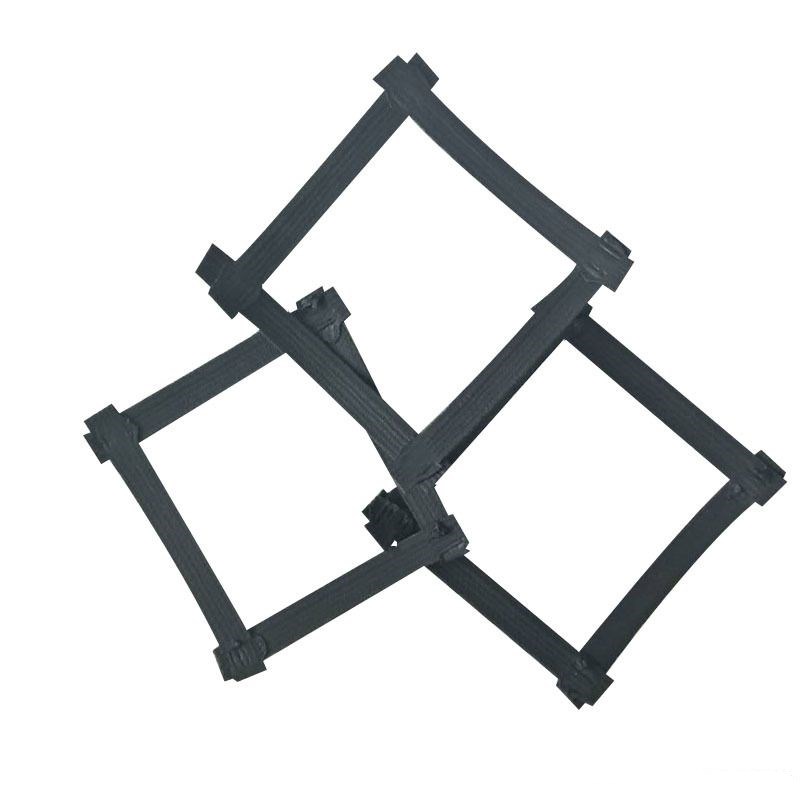

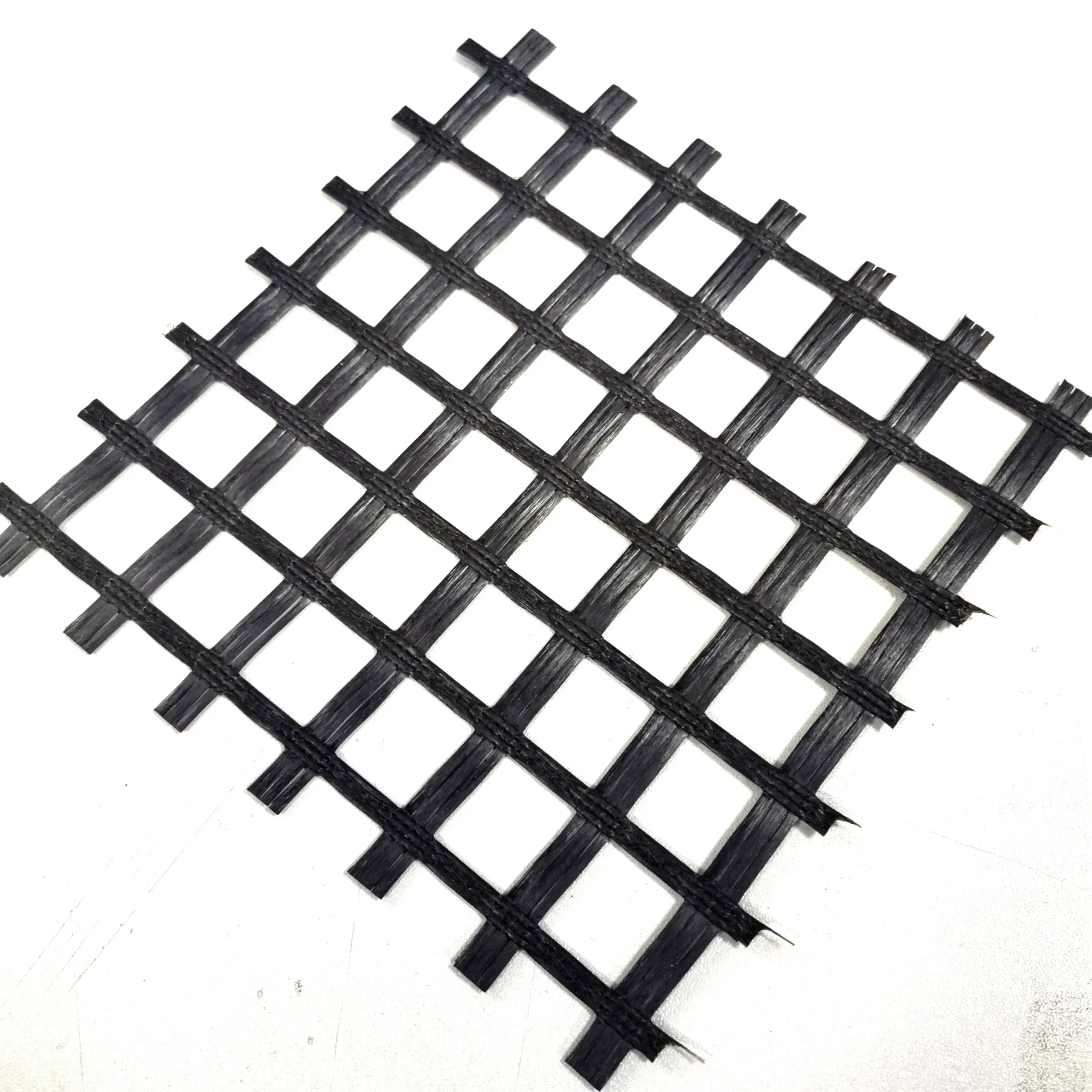

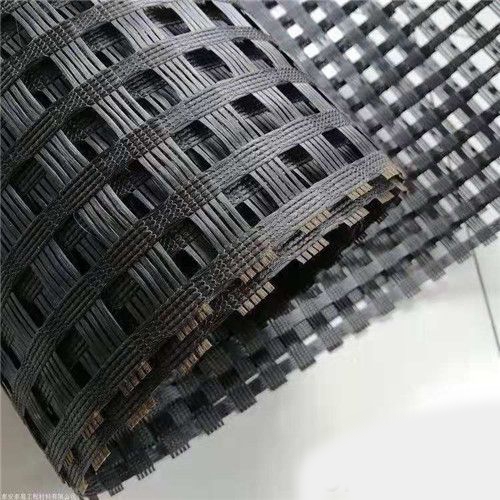

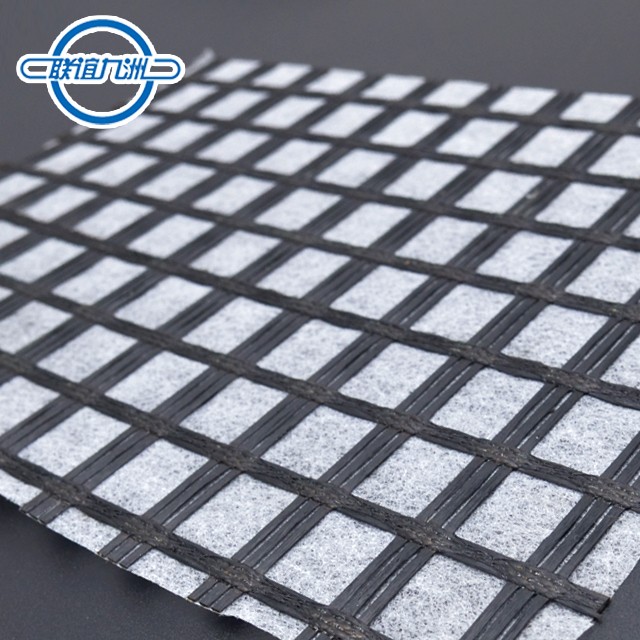

Fiberglass Geogrid

Fiberglass geogrid is a modern designed reinforcement purpose geosynthetic material to strengthen asphalt road surface and road base. Fiberglass geogrid owns high tensile modulus which provides large interlocking strength for asphalt layer at very low elongation, significantly reducing overlay thickness of asphalt and engineering cost accordingly.

Properties of FIBERGLASS GEOGRID,

- Bitumenious polymer impregnated fiberglass grids

- Break elongation at maximum load (≤3%)

- Heat resistance (800 ℃)

- High tensile modulus at very low strain

- Low creep deformation

Fiberglass geogrids offer several advantages that make them an excellent choice for reinforcing asphalt roads:

- High Tensile Strength: Fiberglass geogrids have exceptionally high tensile strength, which allows them to effectively distribute loads and resist cracking and deformation in asphalt pavements. This reinforcement helps to maintain the structural integrity of the road, especially in areas prone to heavy traffic or high loads.

- Durability: Fiberglass is inherently durable and resistant to environmental factors such as moisture, chemicals, and temperature fluctuations. This durability ensures that the geogrid maintains its strength and performance over the lifespan of the asphalt road, reducing the need for frequent repairs or maintenance.

- Reduced Rutting and Reflective Cracking: The use of fiberglass geogrids in asphalt pavements helps minimize rutting, which occurs when the road surface depresses under traffic loads. Additionally, they help mitigate reflective cracking, which is caused by the propagation of cracks from the existing pavement layers to the surface. By providing reinforcement, fiberglass geogrids can effectively limit these forms of distress, thereby extending the service life of the road.

- Improved Fatigue Resistance: Asphalt roads are subjected to repeated loading cycles from vehicular traffic, which can lead to fatigue failure over time. Fiberglass geogrids help enhance the fatigue resistance of asphalt pavements by distributing the applied loads more evenly and reducing stress concentrations, thus delaying the onset of fatigue cracking.

- Ease of Installation: Fiberglass geogrids are lightweight and flexible, making them easier to handle and install compared to traditional materials like steel. This facilitates faster and more cost-effective construction processes, resulting in reduced labor and equipment expenses.

- Compatibility with Asphalt Binders: Fiberglass geogrids are chemically inert and compatible with asphalt binders, ensuring proper adhesion between the geogrid and the pavement layers. This compatibility enhances the effectiveness of the reinforcement and helps maintain the integrity of the asphalt road system.

Material Properties

- Fiberglass Yarn Quality:

- High-strength fiberglass yarns are used, which should meet specific requirements for tensile strength, elongation, and durability.

- The yarns should be free from defects and impurities that could compromise their performance.

- Coating Material:

- The polymer coating, usually PVC, should provide adequate protection against environmental factors such as UV radiation, moisture, and chemical exposure.

- The coating should be uniformly applied to ensure consistent protection across the geogrid.

- Dimensional Stability:

- The geogrid must maintain its shape and dimensions under load and during installation.

- Standards specify acceptable tolerances for the width, length, and aperture size of the geogrid.

Testing Methods

- Tensile Strength Testing:

- The geogrid is subjected to tensile testing to determine its strength and elongation characteristics.

- Tests should be conducted according to ASTM D6637 or ISO 10319 standards.

- Creep Testing:

- Creep tests are conducted to assess the long-term deformation and strength of the geogrid under sustained load.

- This is typically done in accordance with ASTM D5262.

Adhering to strict manufacturing standards for fiberglass geogrid is crucial for ensuring the product’s reliability and performance in civil engineering applications. Standards from organizations like ASTM, ISO, and EN provide comprehensive guidelines for material properties, manufacturing processes, and testing methods. Compliance with these standards ensures that fiberglass geogrids meet the necessary quality and safety requirements, providing effective solutions for soil stabilization, road construction, and other infrastructure projects.

Overall, the use of fiberglass geogrids in asphalt roads offers numerous benefits, including improved structural performance, enhanced durability, and extended service life, making them a preferred choice for engineers and contractors seeking reliable and sustainable pavement solutions.