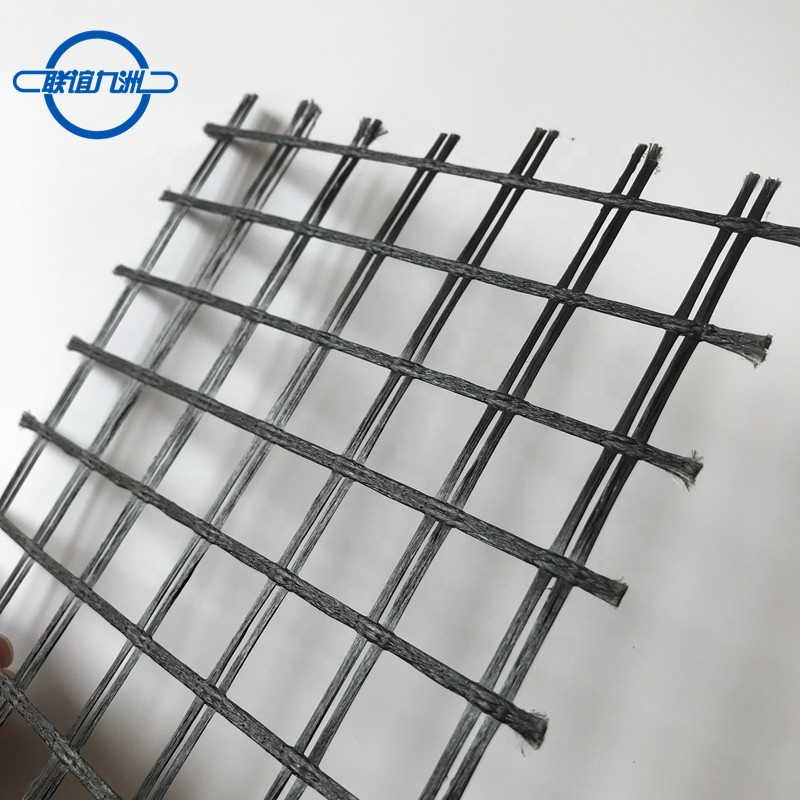

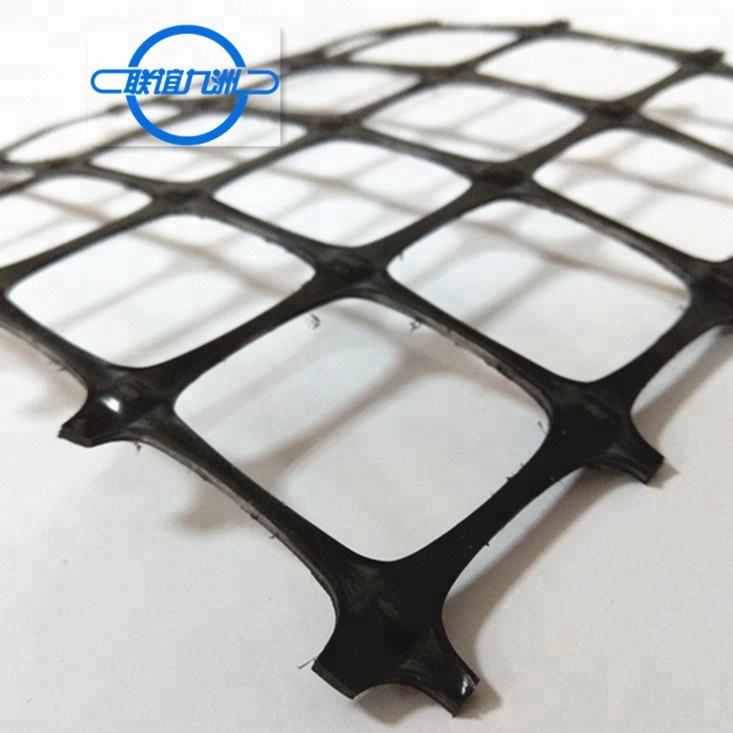

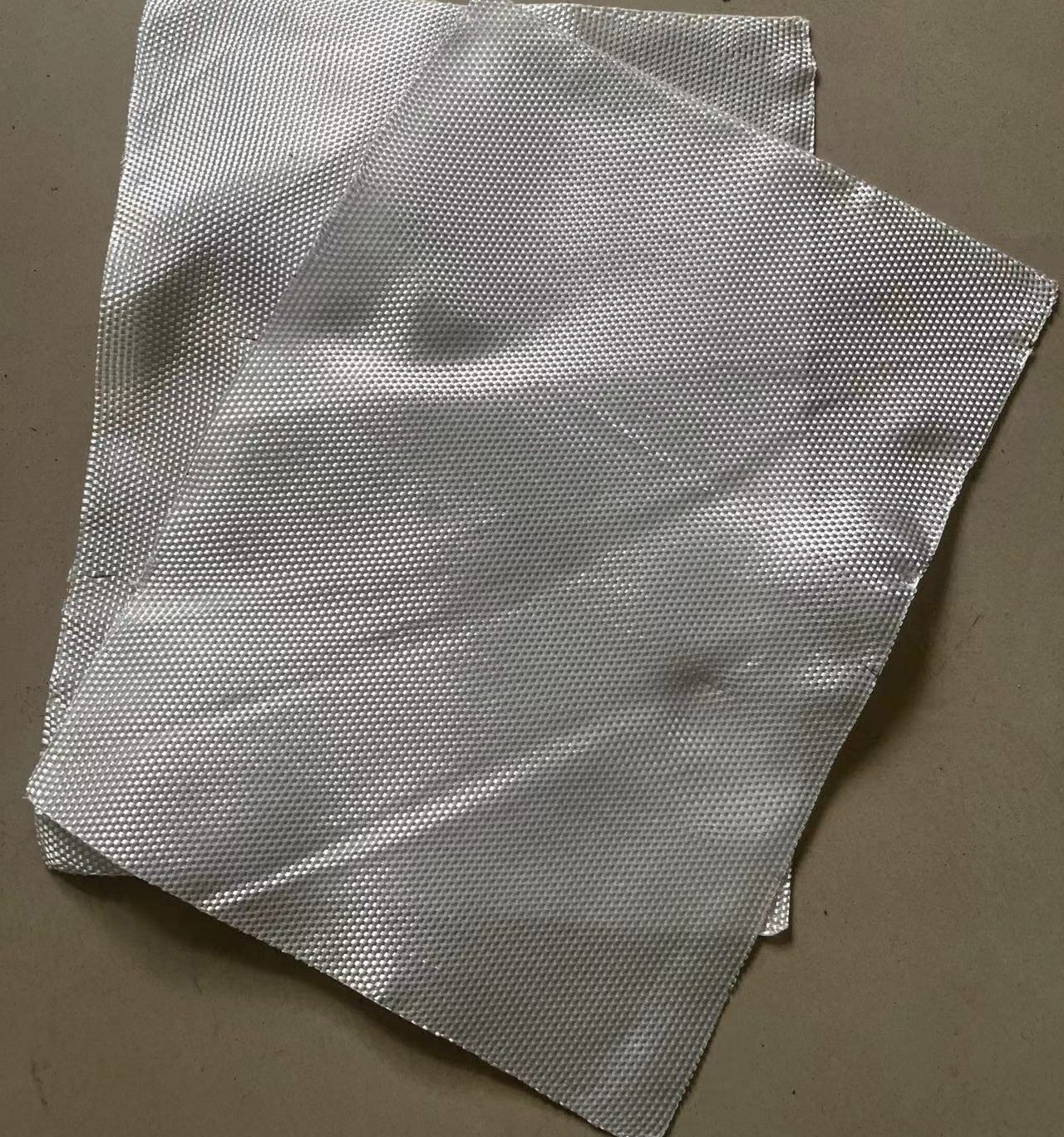

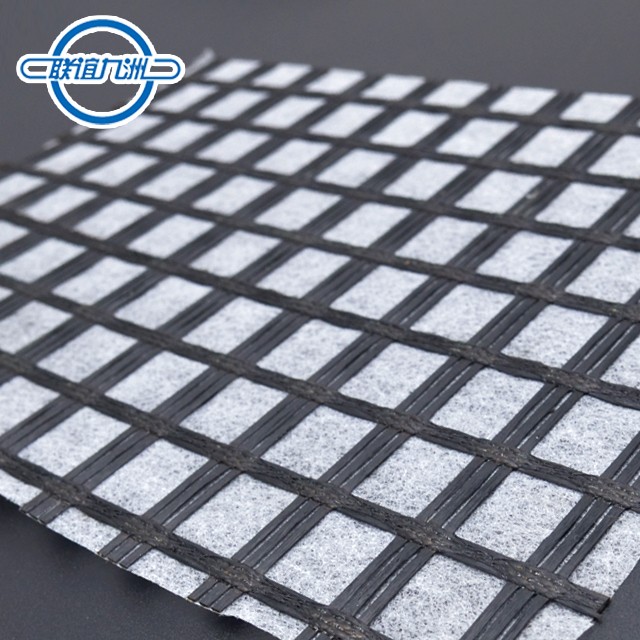

Polyester Woven Geotextile

Material

- Fiber: High-tenacity polyester fibers

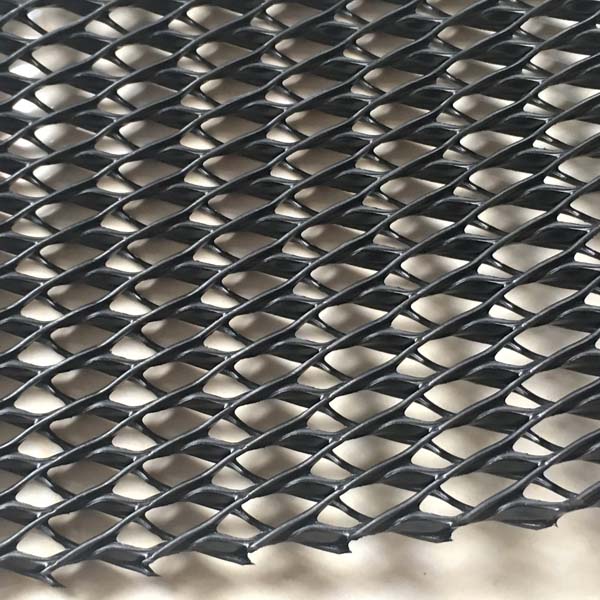

- Weave Type: Plain weave, twill weave, or other specialized weaves depending on application requirements

Properties of Woven Polyester Geotextiles

- High Strength:

- Manufactured from high-tenacity polyester fibers, these geotextiles provide excellent tensile strength and load-bearing capacity.

- Durability:

- Resistant to UV radiation, chemical degradation, and biological attack, ensuring long-term performance even in harsh environments.

- Permeability:

- Designed to allow water to pass through while retaining soil particles, making them ideal for filtration and drainage applications.

- Dimensional Stability:

- Maintains its shape and structure under various loads and conditions.

- Flexibility:

- Flexible enough to conform to irregular surfaces, making installation easier and more effective.

Chemical and Environmental Properties

- UV Resistance: High resistance to degradation from ultraviolet light exposure, which is important for exposed applications

- Chemical Resistance: Resistant to a wide range of chemicals, including acids, alkalis, and organic solvents

- Biological Resistance: Resistant to biological degradation, including resistance to mold, mildew, and bacteria

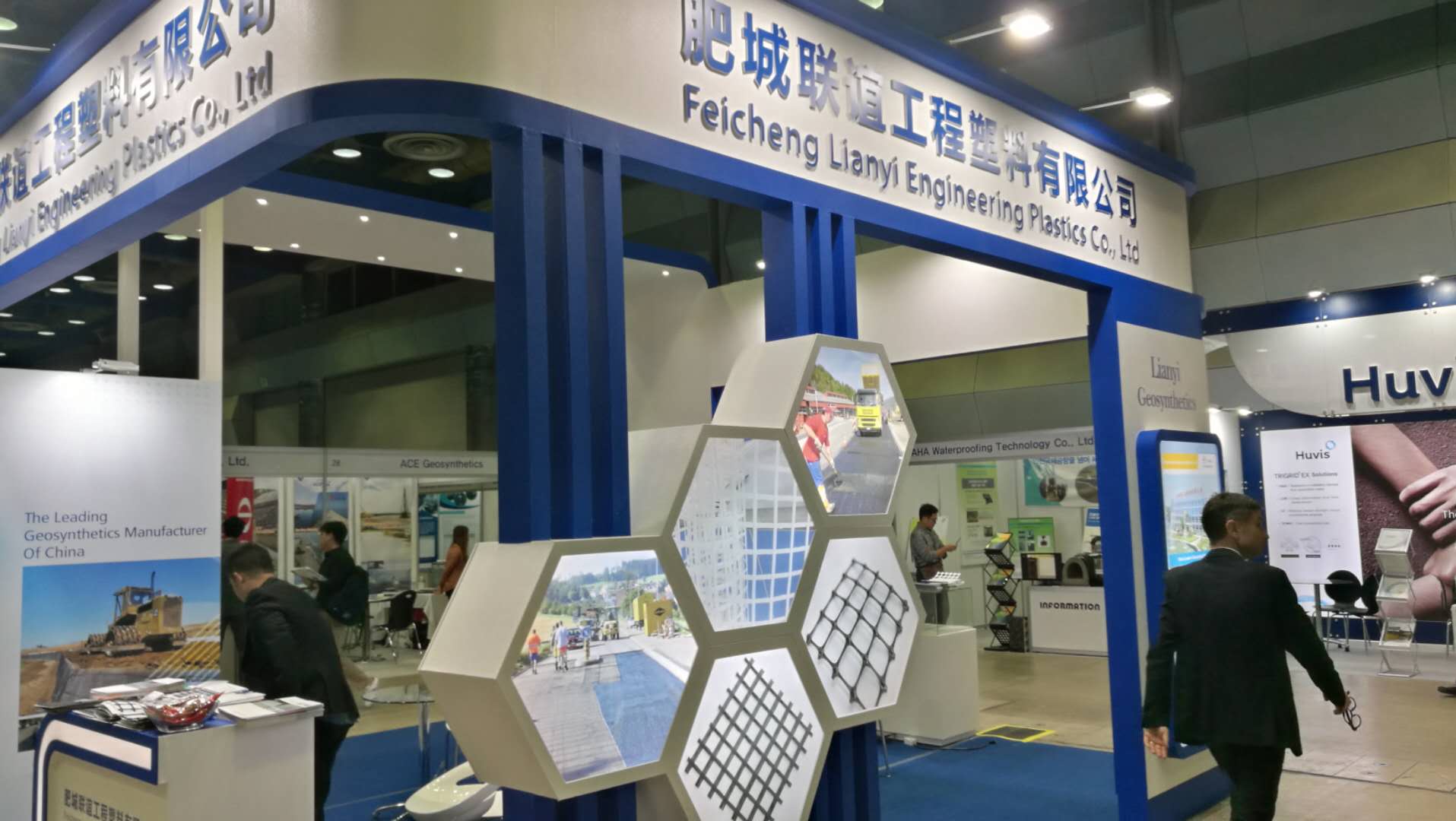

APPLICATIONS:

- Road Construction and Maintenance:

- Separation: Prevents mixing of different soil layers, maintaining the integrity of the road structure.

- Reinforcement: Enhances the load-bearing capacity of roads by distributing loads more evenly.

- Filtration: Allows water to pass through while preventing soil erosion, which is crucial in road drainage systems.

- Railway Construction:

- Provides separation and stabilization of the ballast and subgrade, improving the longevity and performance of railway tracks.

- Erosion Control:

- Used in coastal and riverbank protection to prevent soil erosion by stabilizing the soil and controlling the movement of water.

- Retaining Walls and Slopes:

- Reinforces retaining walls and slopes, enhancing their stability and preventing landslides or soil movement.

- Landfill Liners and Covers:

- Acts as a protective layer in landfill sites, preventing the migration of contaminants and providing structural support.

- Drainage Systems:

- Used in subsurface drainage systems to improve water flow while preventing soil clogging, thus maintaining the effectiveness of the drainage system.

- Pavement Rehabilitation:

- Reinforces old pavements, extending their service life by reducing reflective cracking and improving load distribution.

- Dikes and Embankments:

- Reinforces and stabilizes dikes and embankments, ensuring they can withstand hydraulic pressures and preventing failure.

- Foundations:

- Provides a stable base for building foundations, particularly in areas with poor soil conditions, by distributing loads and preventing settlement.

- Agricultural Applications:

- Used in agricultural fields to prevent soil erosion, improve water management, and enhance crop productivity.

Manufacturing Process

- Fiber Preparation:

- High-tenacity polyester fibers are selected for their strength and durability.

- The fibers are treated with stabilizers to enhance UV and chemical resistance.

- Weaving:

- The fibers are woven together using advanced weaving machines to create a strong, uniform fabric.

- The weaving pattern (plain weave, twill weave, etc.) can be adjusted based on the desired strength and permeability characteristics.

- Heat-Setting:

- The woven fabric is heat-set to stabilize the fibers and lock in the weave pattern, ensuring dimensional stability.

- Finishing:

- The fabric may undergo additional finishing processes, such as coating or laminating, to enhance specific properties like impermeability or abrasion resistance.

- Quality Control:

- Throughout the manufacturing process, rigorous quality control measures are implemented to ensure the geotextile meets the required specifications.

-

Typical Standards and Testing

- ASTM D4595:

- A standard test method for measuring the tensile properties of geotextiles, ensuring consistency and reliability in reported tensile strength values.

- ISO 10319:

- An international standard for determining the tensile strength and elongation of geotextiles.

Example Specifications

Here are some example specifications of tensile strength for different types of woven polyester geotextiles:

- Type A (Low Strength):

- Tensile Strength: 30 kN/m (machine direction) and 20 kN/m (cross-machine direction)

- Elongation at Break: 15% to 20%

- Type B (Medium Strength):

- Tensile Strength: 70 kN/m (machine direction) and 50 kN/m (cross-machine direction)

- Elongation at Break: 10% to 15%

- Type C (High Strength):

- Tensile Strength: 150 kN/m (machine direction) and 100 kN/m (cross-machine direction)

- Elongation at Break: 8% to 12%

- ASTM D4595:

he tensile strength of woven polyester geotextiles is a critical parameter that determines their suitability for various applications. By selecting the appropriate type and strength of geotextile, engineers can ensure effective performance in soil reinforcement, separation, filtration, and other geotechnical applications. For precise specifications and performance characteristics, it is advisable to refer to manufacturer datasheets and conduct standardized testing as per ASTM or ISO guidelines.