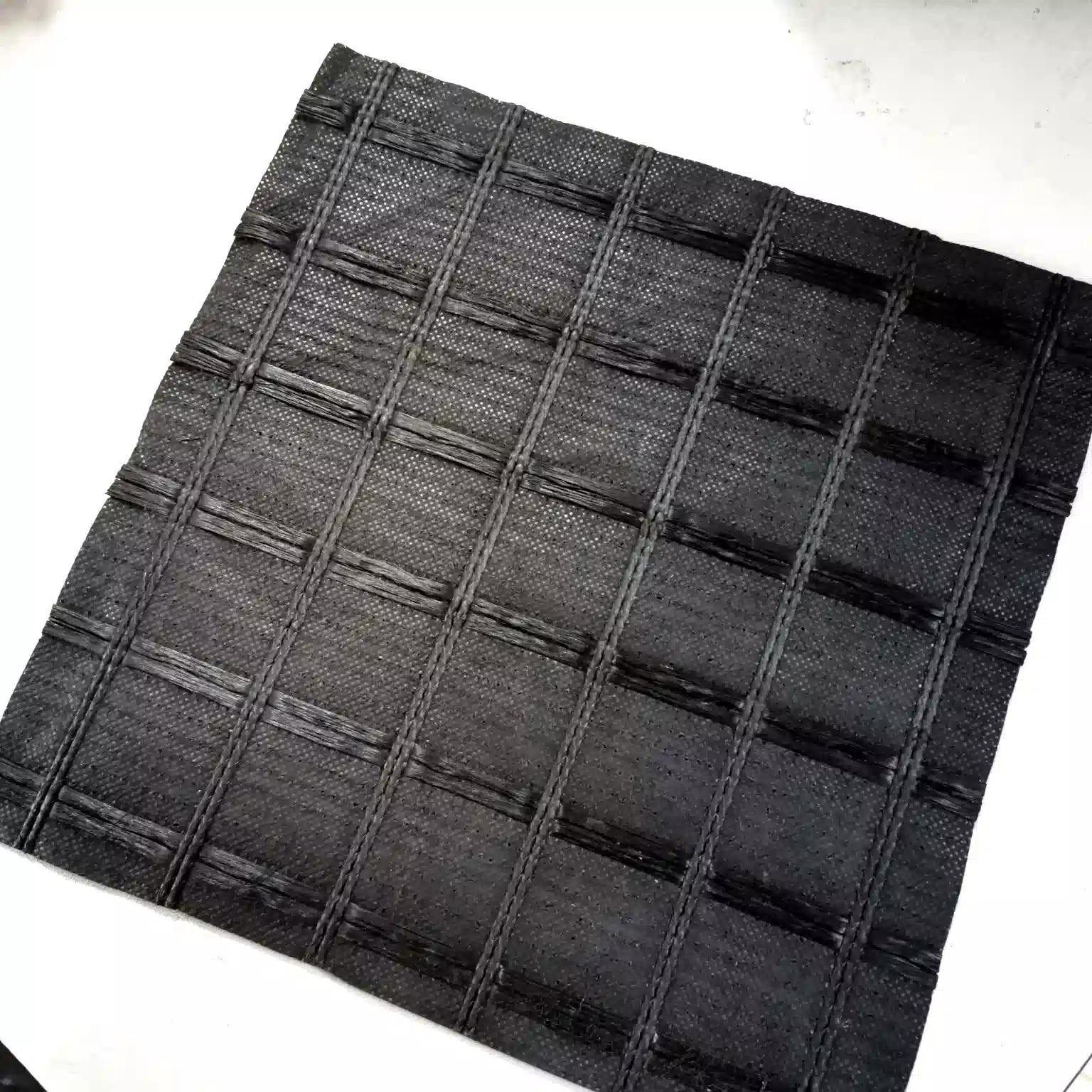

PP WELDED GEOGRID

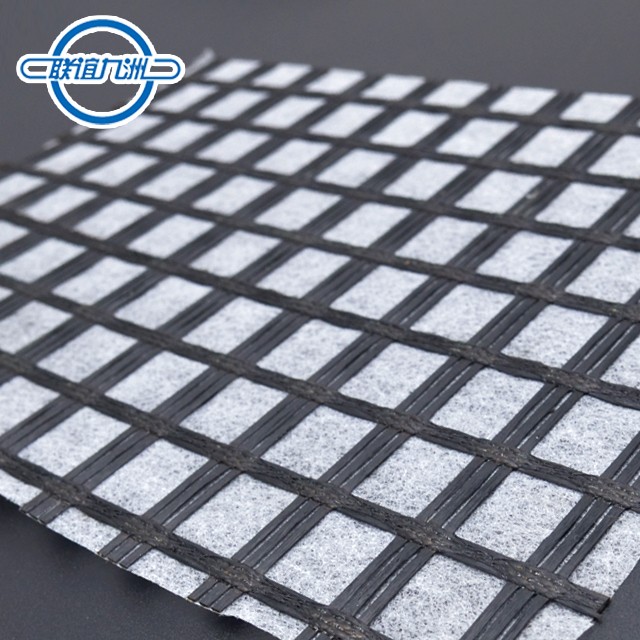

Lianyi’s PP welded geogrids, boasting tensile strengths exceeding 60 kN/m, are engineered to deliver robust reinforcement in various geotechnical applications. These geogrids are designed to provide substantial tensile strength, ensuring enhanced stability and durability in demanding conditions. Here are some key features and applications of Lianyi’s PP welded geogrids with such high tensile strength:

Key Features of Lianyi PP Welded Geogrids (Tensile Strength > 60 kN/m)

- Material Composition:

- Made from high-quality polypropylene (PP) materials, known for their strength, durability, and resistance to environmental factors.

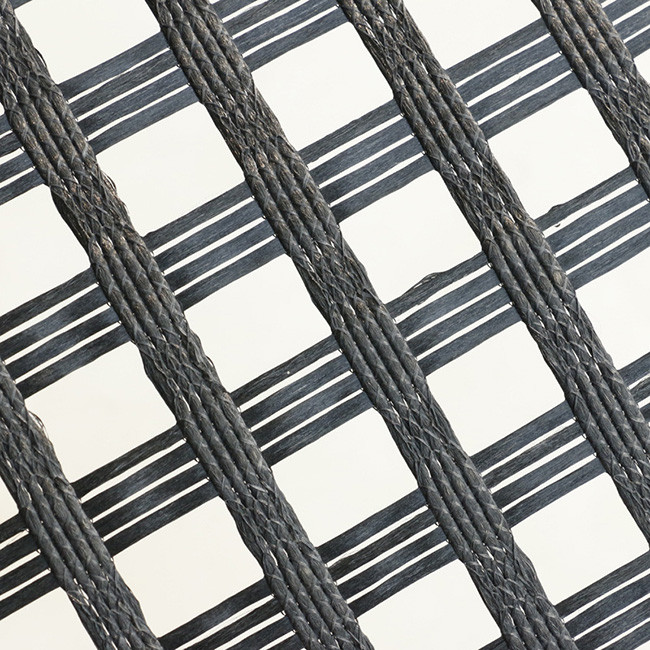

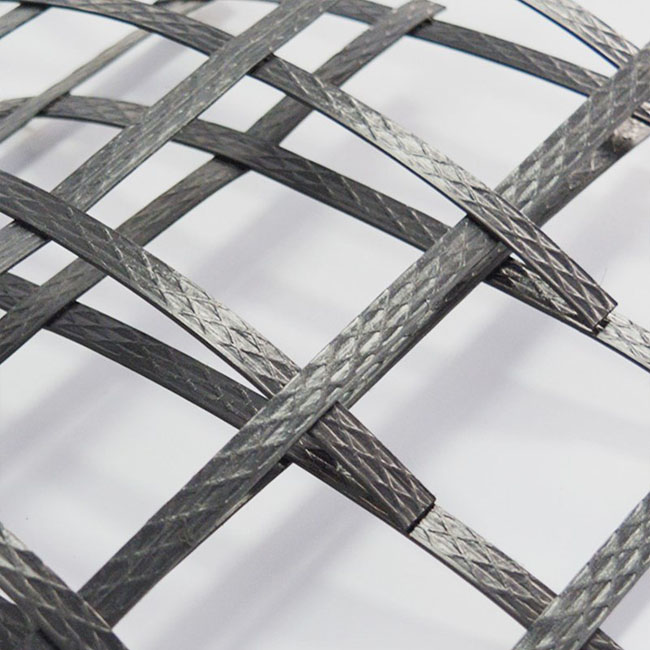

- Welding Technology:

- Utilizes advanced welding techniques to bond the longitudinal and transverse ribs, ensuring uniform strength distribution throughout the geogrid.

- High Tensile Strength:

- Tensile strengths exceeding 60 kN/m indicate the geogrid’s capability to withstand substantial loads and stresses, making it suitable for heavy-duty applications.

- Dimensional Stability:

- Maintains dimensional stability under various soil and environmental conditions, minimizing deformation and enhancing long-term performance.

- Resistance to Environmental Factors:

- Resistant to UV degradation, chemical exposure, and biological deterioration, ensuring longevity and reliability in harsh climates.

- Engineering Standards:

- Complies with international standards and specifications for geosynthetic materials, meeting the stringent requirements of infrastructure projects.

Applications of Lianyi PP Welded Geogrids

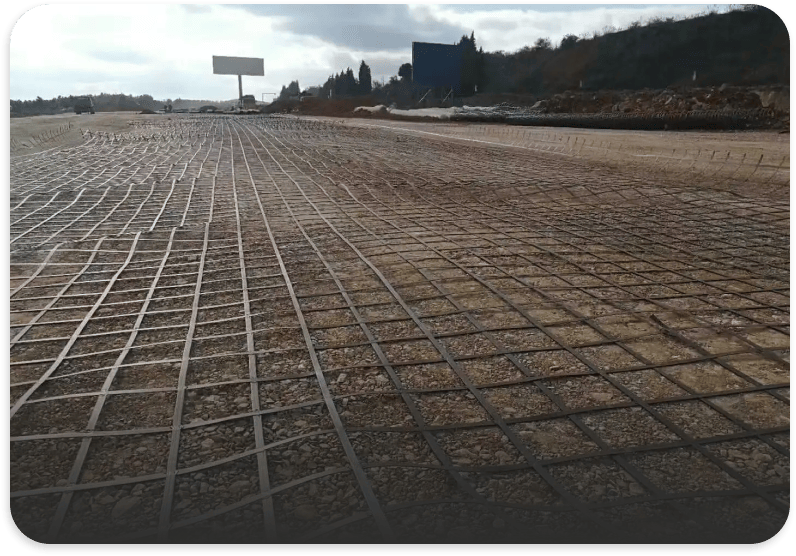

- Road and Pavement Reinforcement: Enhances the structural integrity of road bases and pavements, distributing loads and reducing rutting.

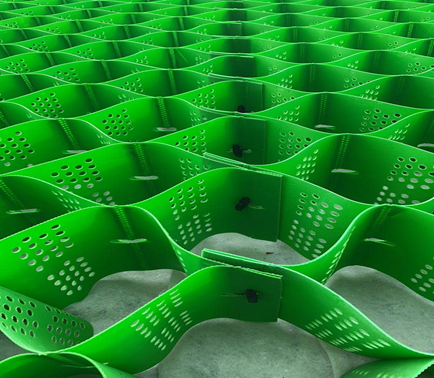

- Retaining Walls and Slope Stabilization: Provides reinforcement for retaining walls, steep slopes, and embankments, preventing soil erosion and instability.

- Foundation Support: Improves bearing capacity and soil confinement around foundations and underground structures.

- Landfill Engineering: Used in landfill liners and caps to enhance stability and containment of waste materials.

Benefits of High-Strength PP Welded Geogrids

- Increased Load-Bearing Capacity: Supports heavy loads and traffic, extending the lifespan of infrastructure.

- Cost-Effectiveness: Reduces maintenance costs by minimizing soil settlement and pavement distress.

- Ease of Installation: Lightweight and flexible for easy handling and installation, reducing construction time and labor.

Key Characteristics of PP Welded Geogrid:

- Material: Made from polypropylene (PP), known for its chemical resistance, flexibility, and durability.

- Manufacturing Process: Extruded PP strips are welded together, creating a strong and integrated grid structure.

- Tensile Strength: Offers high tensile strength, though typically not as high as PET geogrids. It is suitable for many applications where moderate strength is sufficient.

- Elongation: Generally exhibits higher elongation compared to PET, providing some flexibility in applications where slight deformation is acceptable.

- Chemical Resistance: Highly resistant to a wide range of chemicals, making it suitable for environments with potential chemical exposure.

- Durability: Good resistance to UV radiation and biological degradation, ensuring long-term performance.

Lianyi’s PP welded geogrid featured with big aperture size (50mm to 125mm).

The advantages of using a welded geogrid with a larger aperture size (also known as the opening size or grid spacing) depend on the specific application and the engineering requirements. Here are some general advantages associated with larger aperture sizes in welded geogrids:

- Improved Soil Interaction: Larger apertures allow for greater interlock with soil particles, enhancing the geogrid’s ability to stabilize and reinforce soil. This is particularly beneficial in granular soils where the grid can effectively restrain aggregate movement.

- Better Drainage and Filtration: Larger openings facilitate better water drainage through the geogrid, preventing hydrostatic pressure build-up behind retaining walls or slopes. This can also aid in maintaining soil stability by reducing the risk of water saturation and erosion.

- Enhanced Installation Efficiency: Geogrids with larger apertures are often easier to handle and install due to reduced material stiffness and increased flexibility. This can lead to faster installation times and potentially lower labor costs.

- Reduced Material Costs: In some cases, using a geogrid with larger apertures can reduce material costs compared to finer grids, especially when covering larger areas or when the primary requirement is reinforcement rather than soil separation.

- Compatibility with Coarser Aggregates: Larger aperture sizes accommodate coarser aggregates and fill materials more effectively, making them suitable for applications where robust soil reinforcement is required with minimal risk of clogging or blockage.

- Effective Vegetation Growth: In environmental applications or green infrastructure projects, larger apertures can promote the growth of vegetation through the geogrid, facilitating natural erosion control and soil stabilization over time.

- Structural Stability: When used in structural applications such as road construction or retaining walls, geogrids with larger apertures can contribute to improved structural stability by distributing loads more evenly and reducing differential settlement.