HDPE GEOCELL

Introduction

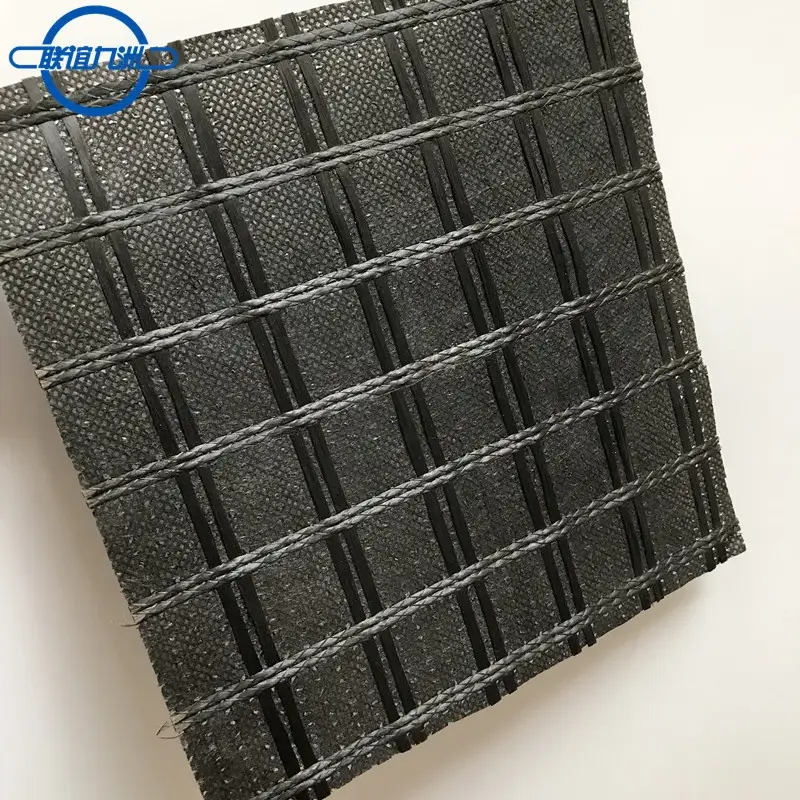

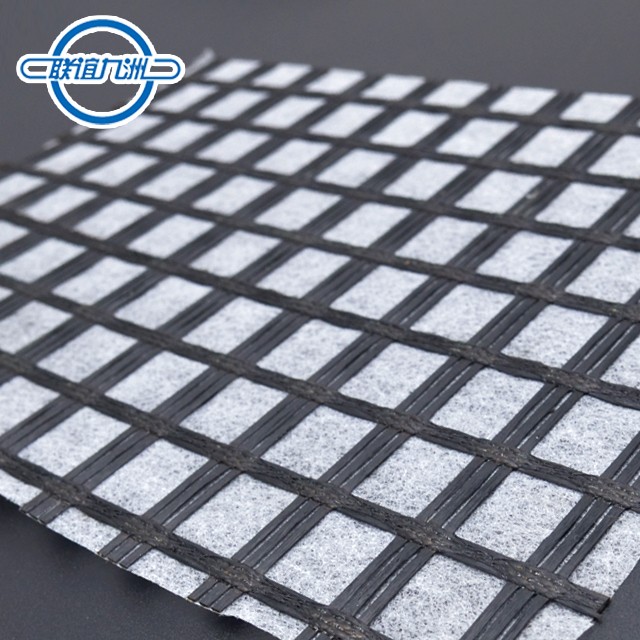

Geocell mechanical properties:

- Stable performance and strong adaptability

Light material, wear-resistant, stable chemical properties, light aging resistance, acid and alkali resistance,

suitable for different soil and desert geological conditions

- High tensile strength and strong bearing capacity

The tensile strength of the material and weld seam is high. The high lateral limit and anti slip deformation

effectively enhance the bearing capacity of the roadbed and disperse the load

- Strong erosion resistance, anti slip, anti deformation

Corrosion resistant, with high bearing capacity and good dynamic performance, strong erosion resistance, and good soil consolidation effect High flexibility and good slope stability

- Geometric dimensions, convenient construction, customizable

Geometric dimensions to meet different engineering needs. Flexible and retractable, with small transportation volume; The main accessories are overlapped, efficient and convenient, and the construction speed is fast

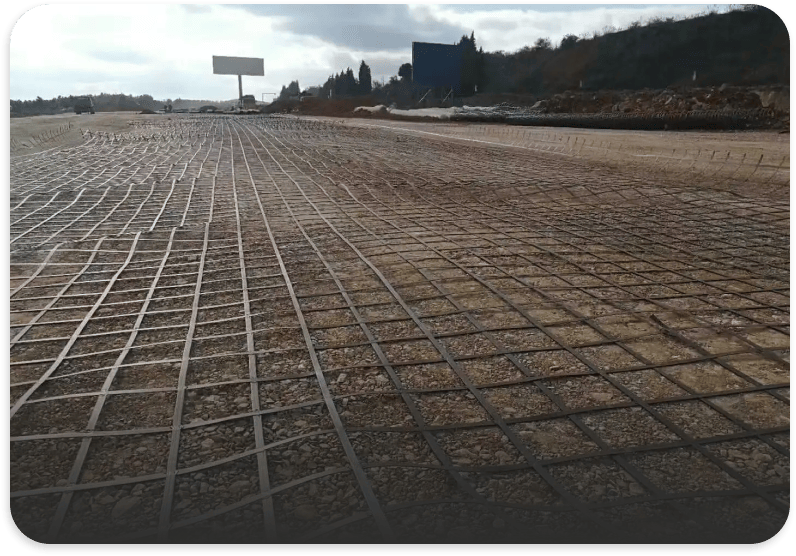

Choose Geocell for typical Applications

- Road and Pavement Construction: Reinforcing base layers to enhance the load distribution and prevent rutting and settlement.

- Slope and Channel Protection: Preventing erosion and promoting vegetation on steep slopes and waterways.

- Retaining Structures: Building gravity and reinforced retaining walls.

- Load Support: Providing stable foundations for heavy loads in areas like parking lots, industrial yards, and railway tracks.

- Environmental and Landscaping Projects: Stabilizing soil in green roofs, retaining walls, and landscape features.

Load Support

-

Basic stability

Acting as a foundation support beneath the surface/subsurface of the pavement, the Cell Load Support System creates a stabilizing layer beneath asphalt, concrete or modular pavements that can withstand heavy, repetitive traffic. The system acts like a semi-rigid slab, spreading loads laterally and reducing foundation contact pressures.

-

Surface stabilization

The Cell Surface Stabilization System provides a more cost-effective alternative to hard-surface pavement with many environmental advantages. The system improves the load distribution characteristics of unpaved roads and sidewalks, reducing long-term maintenance needs and costs.

Quick and Easy Installation

Geocells are lightweight and easy to handle, making them quick to install. This can lead to faster project completion times and reduced labor costs.

By incorporating geocells into civil engineering projects, engineers and builders can achieve more stable, durable, and cost-effective solutions for a variety of geotechnical challenges.

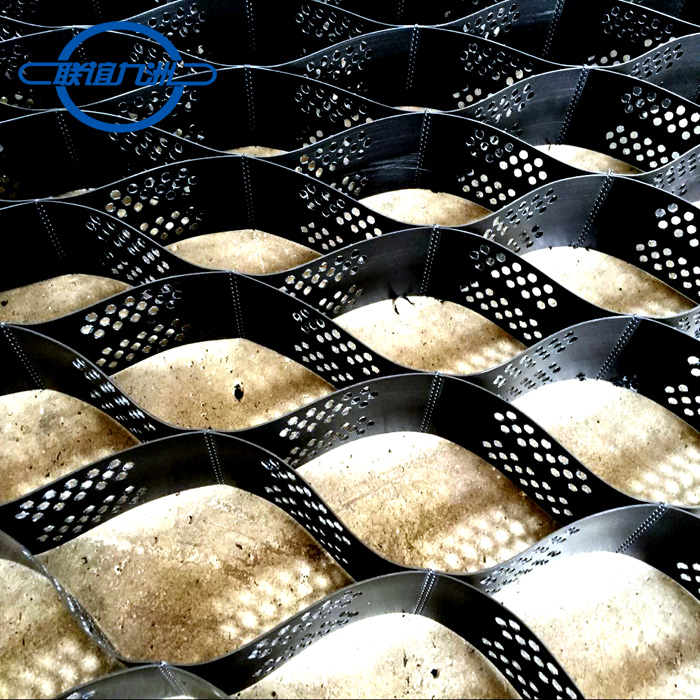

An advanced HDPE (High-Density Polyethylene) extrusion machine for Geocell sheet production is crucial for manufacturing high-quality cellular confinement systems used in various civil engineering and environmental applications. Geocells are three-dimensional honeycomb-like structures made from HDPE sheets that are welded or fused together to create a stable cellular matrix. Here’s an overview of the process and features of an advanced HDPE extrusion machine used for Geocell sheet production:

Manufacturing Process of Geocell Sheets

- Material Selection:

- High-Density Polyethylene (HDPE): Selected for its durability, chemical resistance, and flexibility. HDPE is extruded into sheets of specified thickness and width.

- Extrusion Process:

- Extruder: The HDPE resin is melted and conveyed through an extruder, where it is heated to a precise temperature and pressure.

- Die Head: The molten HDPE is forced through a die head that shapes it into a continuous flat sheet of uniform thickness.

- Sheet Formation:

- Calibration and Cooling: The extruded sheet passes through a calibration and cooling system to ensure dimensional accuracy and stability.

- Surface Treatment (Optional): Surface treatment techniques such as corona treatment may be applied to enhance adhesion properties for subsequent processes.

- Geocell Structure Formation:

- Sheet Folding: The extruded HDPE sheet undergoes folding using specialized folding mechanisms that create a series of parallel creases or folds at regular intervals.

- Ultrasonic Welding (Optional): For advanced Geocell production, ultrasonic welding technology may be employed to fuse the folded edges together, ensuring strong seams and structural integrity.

- Perforation (Optional):

- The HDPE sheet may be perforated during or after extrusion to allow for drainage or vegetation growth within the Geocell structure.

- Quality Control:

- Continuous monitoring and inspection ensure that the Geocell sheets meet dimensional tolerances, material strength requirements, and other quality specifications.

- Sample testing for tensile strength, weld integrity, and environmental resistance ensures compliance with industry standards.

- Rolling and Packaging:

- Once manufactured, the Geocell sheets are rolled onto spools or cut into specified lengths and packaged for transportation and storage.