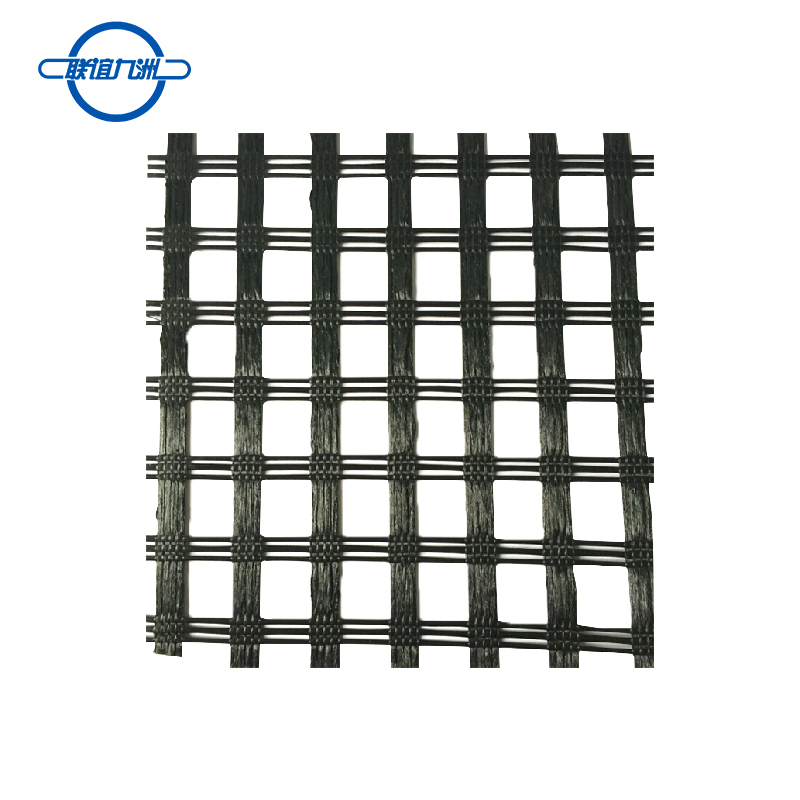

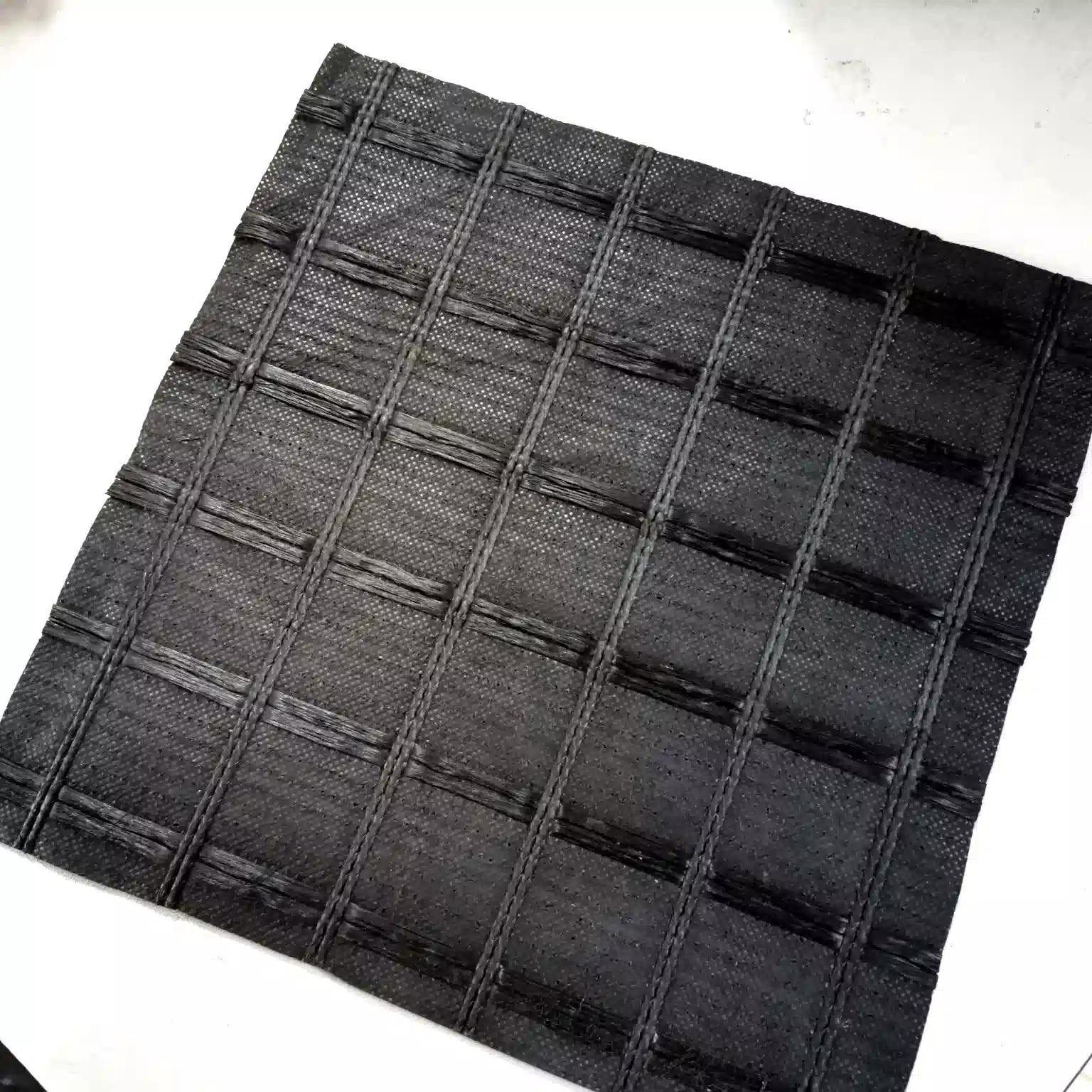

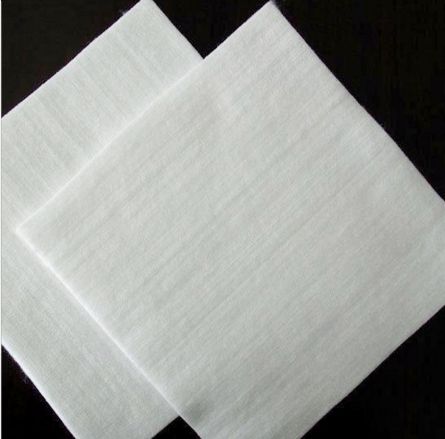

PP Nonwoven Geotextile

Characteristics:

- High Tensile Strength: Provides excellent strength to withstand heavy loads and stress.

- Durability: Resistant to degradation from chemicals, microorganisms, and environmental factors.

- Permeability: Allows water to pass through while filtering out soil particles, preventing soil erosion.

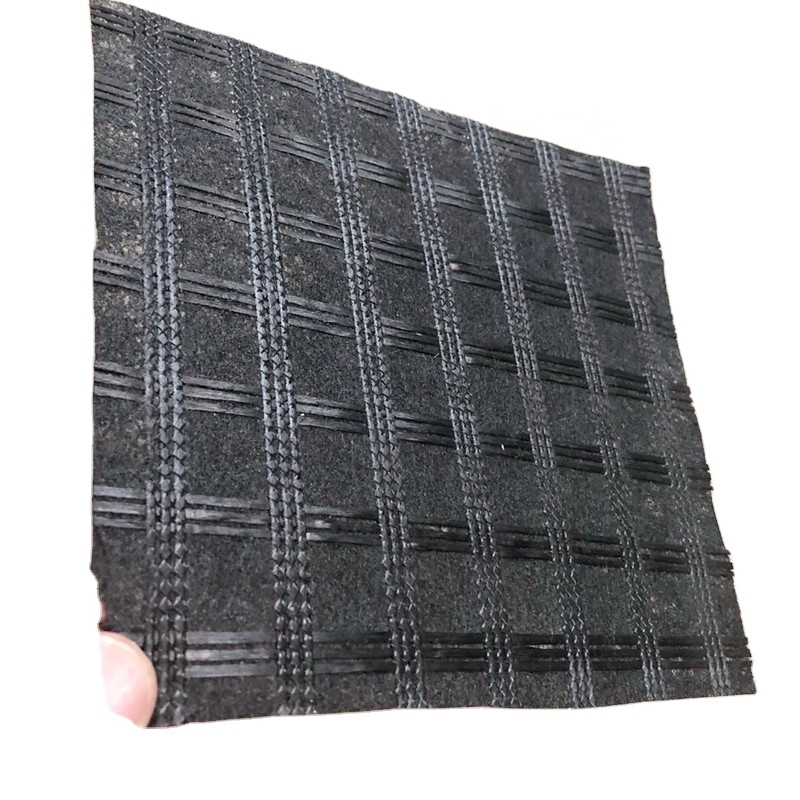

- Flexibility: Can conform to ground contours and irregular surfaces, ensuring effective coverage and performance.

- UV Resistance: Resists degradation from ultraviolet radiation, making it suitable for outdoor use.

- Lightweight: Easy to handle and install, reducing labor costs and effort.

- Cost-Effective: Offers an economical solution for a wide range of geotechnical applications.

- Non-Toxic: Safe for use in environmental and agricultural applications.

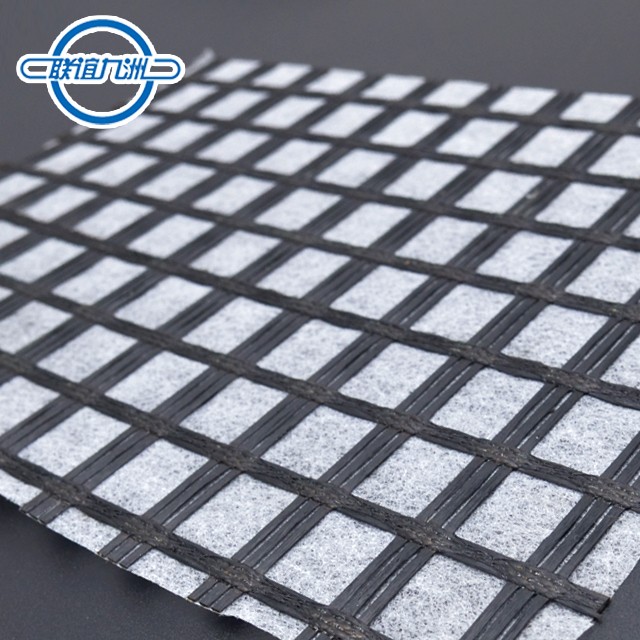

Applications:

- Soil Stabilization: Reinforces soil structure in construction projects, preventing shifting and erosion.

- Erosion Control: Protects slopes, riverbanks, and shorelines from erosion by stabilizing the soil.

- Drainage Systems: Facilitates proper drainage in roads, highways, and other construction projects by allowing water to pass through while retaining soil particles.

- Road Construction: Enhances the durability and lifespan of roads by providing a stable base and reducing rutting.

- Landfills: Acts as a protective layer in landfill construction, preventing contamination of the surrounding environment.

- Retaining Walls: Provides structural support and improves the stability of retaining walls.

- Agriculture: Used for soil moisture retention and weed control in agricultural fields.

- Environmental Protection: Used in applications such as sediment control and water filtration to protect natural resources.

Lianyi Company is committed to provide continuous improvement of geotextile-related products. Producing high-quality polypropylene nonwoven geotextiles requires advanced extrusion equipment tailored to handle the specific characteristics and demands of the material. Here are the key features and considerations for selecting precision extrusion equipment for manufacturing polypropylene nonwoven geotextiles:

Features of Precise Extrusion Equipment for Polypropylene Nonwoven Geotextiles

- Extruder Design:

- Single or Multi-Screw Extruders: Choose an extruder suitable for processing polypropylene (PP) resin, capable of maintaining precise temperature control and consistent melt flow.

- High Torque Motors: Ensure the extruder is equipped with high torque motors for reliable performance at varying speeds and pressures.

- Melt Filtration System:

- Include an effective melt filtration system to remove contaminants and ensure the purity of the PP resin, preventing defects in the final geotextile.

- Die Design:

- Slot Die or Sheet Die: Opt for a die design that facilitates uniform distribution of the molten PP resin onto the forming surface.

- Adjustable Lip Gap: Allows for precise control over the thickness and uniformity of the extruded web.

- Web Formation:

- Spinbonding Technology: Use spinnerets to extrude polypropylene filaments directly onto a moving conveyor belt, creating a random or controlled orientation of fibers.

- Cross-lapping Mechanism: Employ a cross-lapping system to layer and interlace the filaments, ensuring uniform web formation and strength.

- Bonding Mechanism:

- Thermal Bonding: Implement a thermal bonding process using heated calender rollers to fuse polypropylene fibers together, enhancing fabric strength and durability.

- Needle-Punching: Alternatively, integrate a needle-punching mechanism to mechanically entangle fibers, creating a robust nonwoven structure.

- Calendering and Finishing:

- Utilize calender rollers to compact and smooth the surface of the nonwoven geotextile, improving fabric integrity, uniformity, and surface characteristics.

- Apply surface treatments such as coatings or additives for enhancing UV resistance, hydrophobicity, or other specific performance attributes.

- Process Control and Automation:

- Incorporate advanced control systems to monitor and regulate extrusion parameters including temperature, pressure, speed, and tension.

- Implement automation for precise adjustment of process variables, ensuring consistent production and quality.

- Quality Assurance:

- Integrate real-time monitoring and quality control systems to detect and address defects promptly during production.

- Conduct regular testing of finished geotextiles for key properties such as tensile strength, tear resistance, puncture resistance, permeability, and dimensional stability.

Considerations for Selecting Extrusion Equipment

- Capacity and Output: Choose equipment that meets the desired production capacity and output requirements for nonwoven geotextiles.

- Flexibility: Opt for equipment that allows flexibility in adjusting parameters to accommodate varying material specifications and production demands.

- Energy Efficiency: Select equipment with energy-efficient features to minimize operational costs and environmental impact.

- Maintenance and Support: Consider the availability of technical support, spare parts, and maintenance services from the equipment supplier.