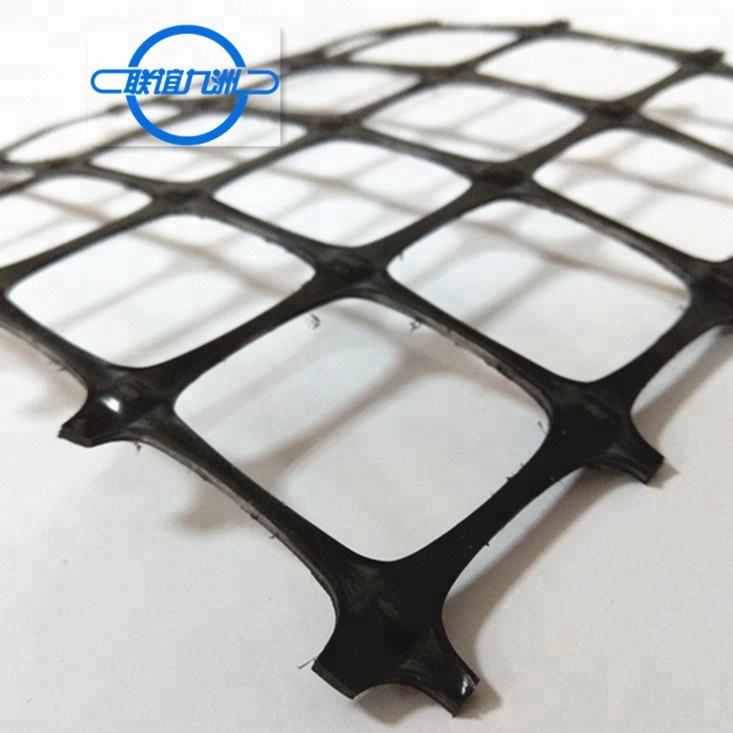

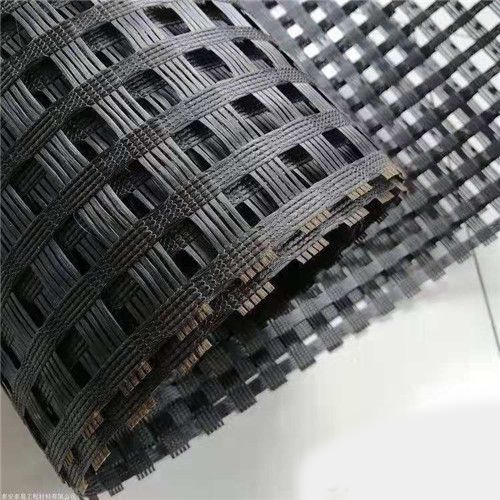

POLYESTER GEOGRID-BIAXIAL TYPE

Introduction

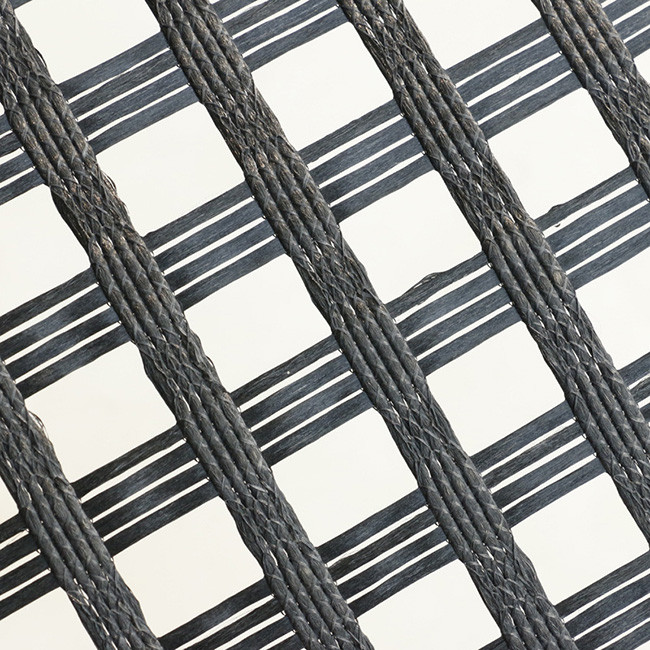

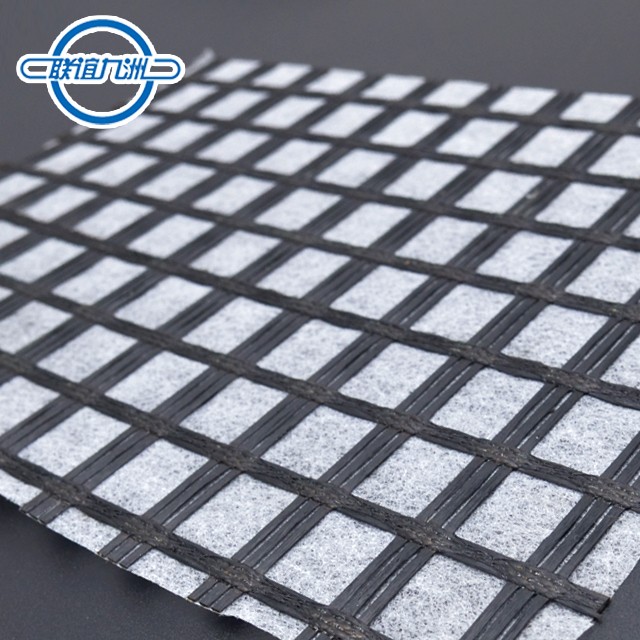

Lianyi polyester geogrid is made from high tenacity polyester yarn through warp-knitting and PVC coating process to provide reinforcement support in both longitudinal and transverse orientations.

Choose polyester geogrid

Key Features

- High Tensile Strength:

- Polyester biaxial geogrids are made from high-tenacity polyester yarns, providing superior tensile strength in both directions. This strength ensures effective soil reinforcement and structural stability.

- Durable Polymer Coating:

- The geogrids are coated with a durable polymer, enhancing their resistance to environmental factors such as UV radiation, moisture, and chemicals. This coating extends the lifespan of the geogrids even in harsh conditions.

- Biaxial Structure:

- The biaxial design ensures that the geogrids can handle loads applied in multiple directions, making them ideal for applications where multidirectional strength is required.

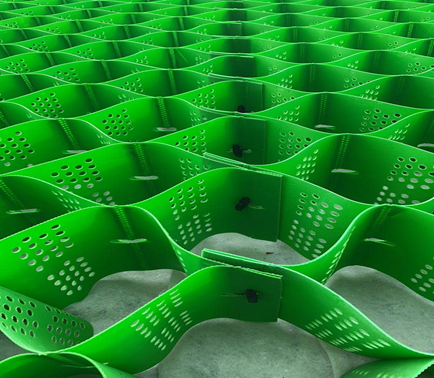

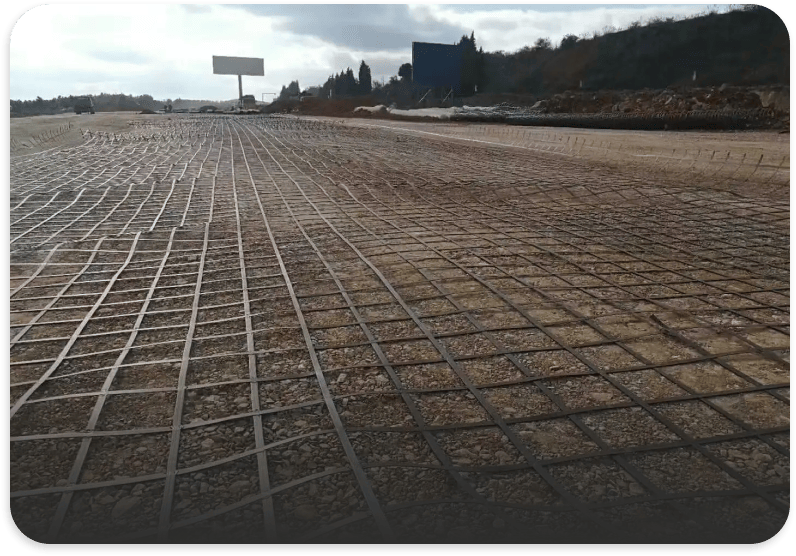

Applications

- Road Construction:

- Used to reinforce subgrades and base layers, asphalt road surface, improving the longevity and performance of roadways.

- Railway Reinforcement:

- Enhances the stability and durability of railway tracks by providing effective load distribution.

- Retaining Walls:

- Improves the structural integrity of retaining walls, preventing soil erosion and movement.

- Embankments:

- Provides reinforcement for embankments, ensuring stability and preventing settlement.

- Landfills:

- Used in landfill construction to reinforce the base and cap layers, ensuring long-term stability.

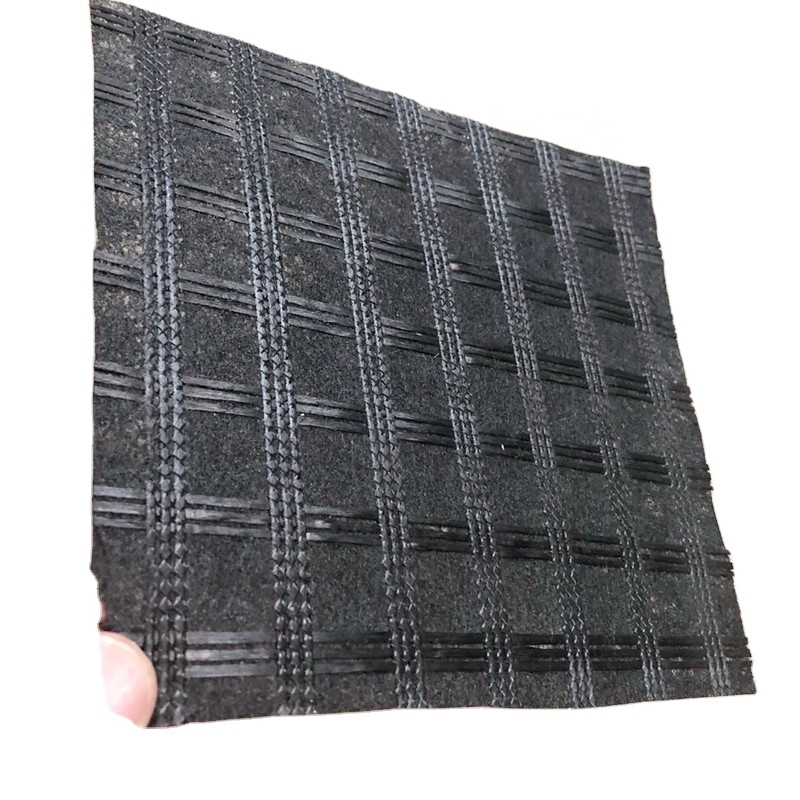

PVC-coated polyester geogrids are specialized geosynthetic materials used in civil engineering for applications such as soil reinforcement, slope stabilization, and pavement reinforcement. The design and manufacturing process of these geogrids involves selecting high-quality materials, precise knitting, and coating techniques to produce durable and high-performance products. This document provides an overview of the design considerations, manufacturing processes, and quality control measures involved in producing PVC-coated polyester geogrids.

Design Considerations

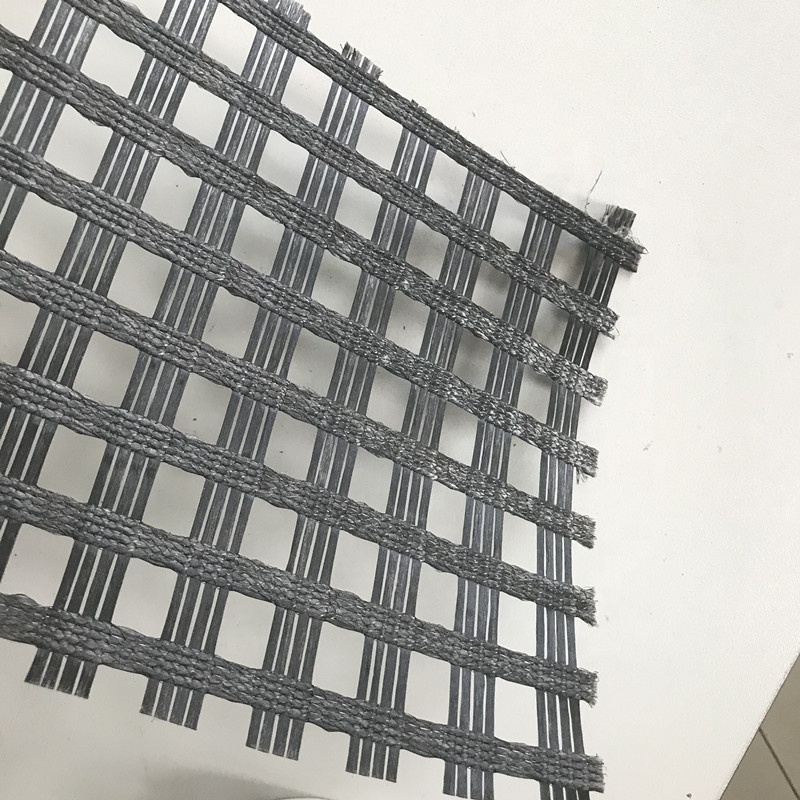

- Material Selection:

- Polyester Yarns: Polyester is chosen for its high tensile strength, low creep characteristics, and excellent resistance to environmental degradation.

- PVC Coating: Polyvinyl chloride (PVC) is selected for its durability, flexibility, chemical resistance, and UV stability, which protects the underlying polyester yarns.

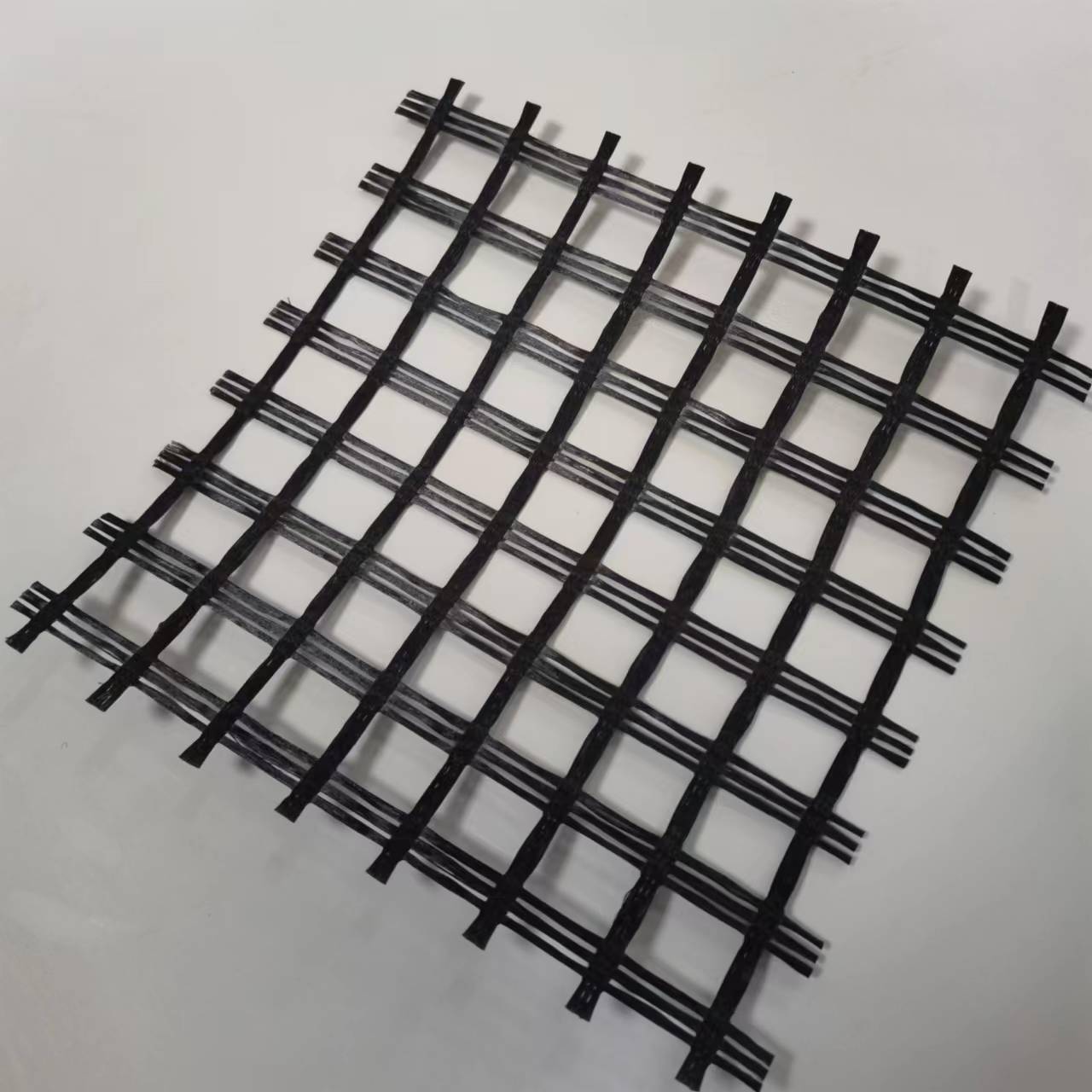

- Geogrid Structure:

- Aperture Size and Shape: The size and shape of the openings in the geogrid are designed to optimize soil interlocking and load distribution.

- Knitting Pattern: The knitting pattern of the polyester yarns is engineered to provide maximum strength and stability while ensuring even distribution of the coating.

- Performance Requirements:

- Tensile Strength: The geogrid must withstand high tensile forces without breaking.

- Elongation: The geogrid should have limited elongation to maintain structural integrity under load.

- Durability: The geogrid must resist chemical, biological, and UV degradation over its service life.

Manufacturing Process

- Yarn Preparation:

- High-tenacity polyester yarns are selected and prepared for knitting. These yarns undergo quality checks to ensure they meet specified tensile strength and elongation requirements.

- Knitting Process:

- Warp Knitting: Polyester yarns are warp-knitted into a grid structure. Warp knitting is preferred due to its ability to produce a stable, dimensionally consistent geogrid with high tensile strength.

- Quality Control: During knitting, continuous monitoring ensures the correct alignment and tension of the yarns to produce a uniform grid structure.

- Coating Application:

- Coating Preparation: PVC is mixed with stabilizers, plasticizers, and other additives to enhance its performance characteristics.

- Coating Process: The knitted polyester grid is coated with PVC using a dip-coating or extrusion-coating process. In dip-coating, the grid is immersed in the PVC solution, while in extrusion-coating, the PVC is extruded onto the grid.

- Curing: After coating, the geogrid is cured at controlled temperatures to ensure proper adhesion of the PVC to the polyester yarns and to achieve the desired flexibility and durability.

- Final Inspection and Testing:

- Dimensional Checks: The geogrid is inspected for uniform aperture size, correct dimensions, and consistent coating thickness.

- Mechanical Testing: Samples are tested for tensile strength, elongation, and coating adhesion to ensure they meet the required specifications.

PVC-coated polyester geogrids provide high performance and durability for various civil engineering applications. Ensuring their quality involves stringent testing and quality control measures. Tests for tensile strength, creep resistance, chemical and UV resistance, and coating adhesion are essential to guarantee the geogrid’s reliability. Continuous monitoring of production processes and regular audits help maintain high standards, ensuring that the geogrids perform effectively in reinforcing and stabilizing soil and pavement structures.