PP BIAXIAL GEOGRID

Introduction

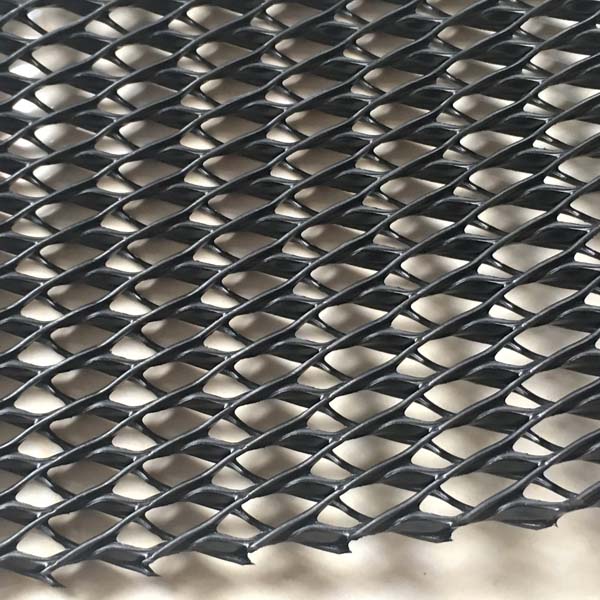

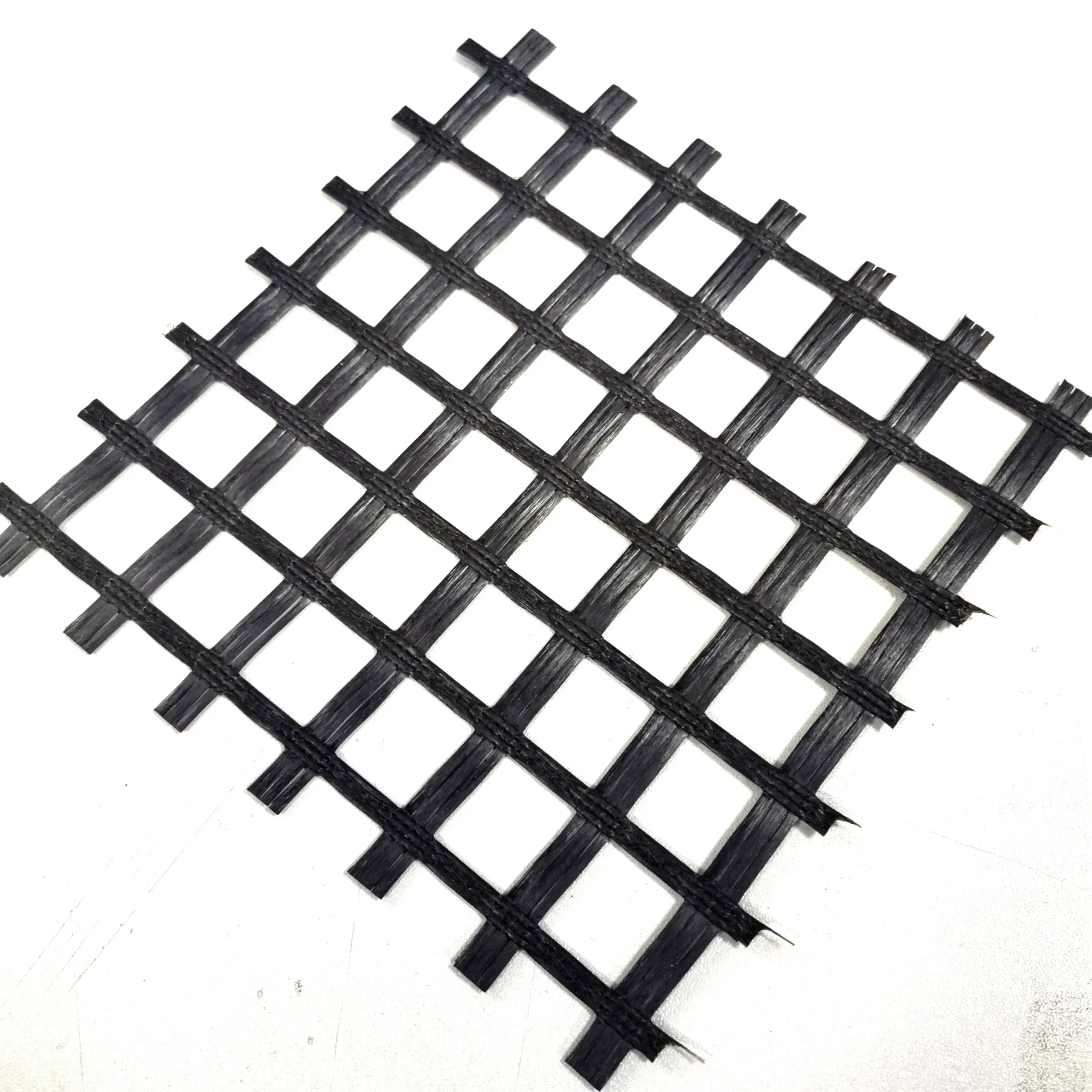

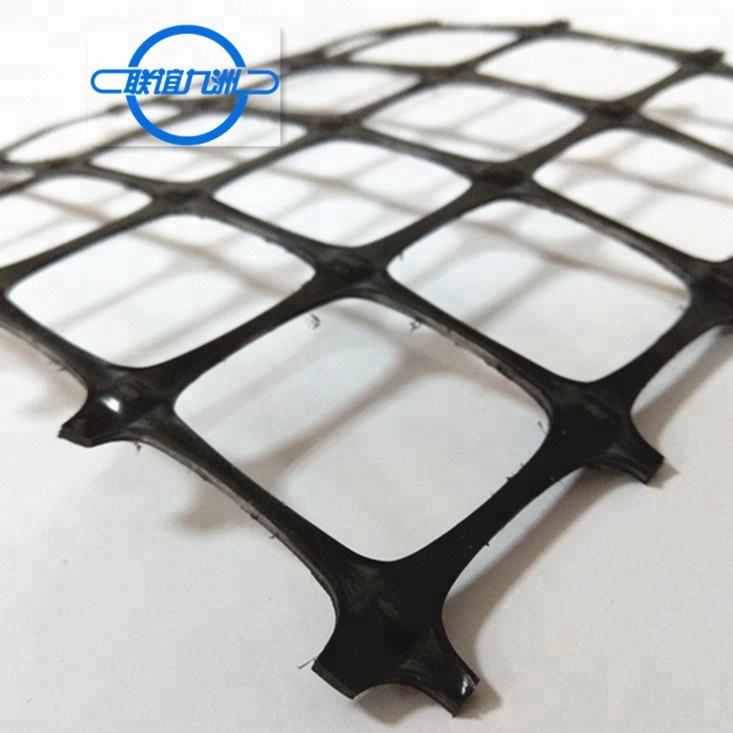

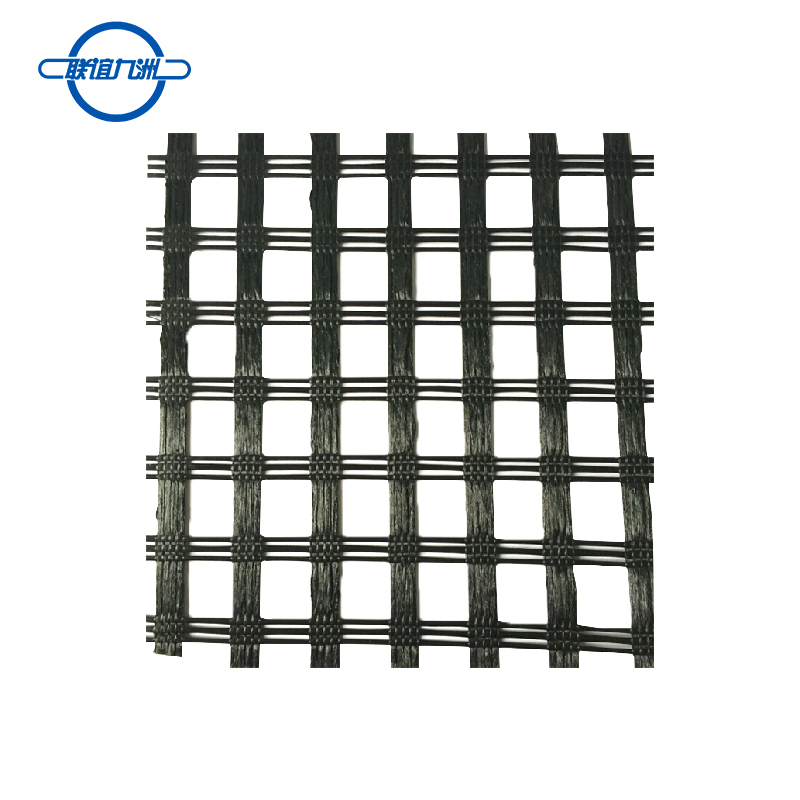

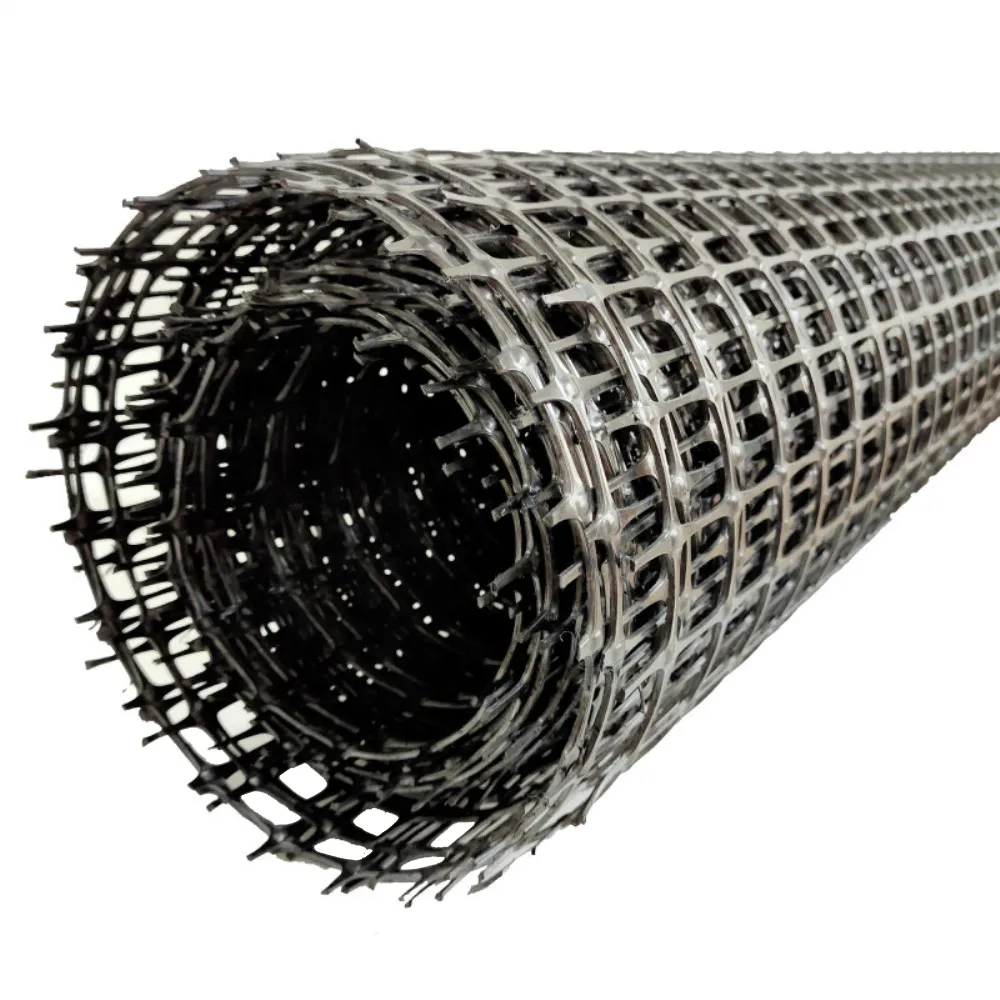

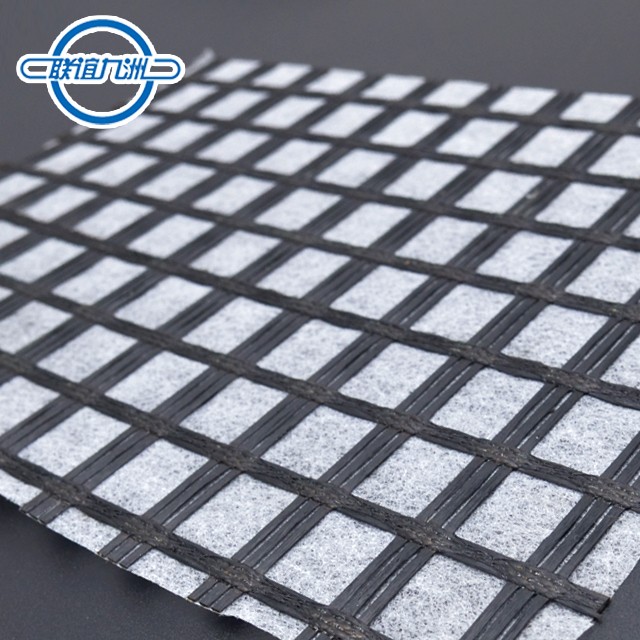

Polypropylene biaxial geogrid is made from high purity polypropylene resin supplemented by crucial additives to enhance tensile strengthes at both directions and prolong design service life.

Properties of PP Biaxial Geogrid

- Integrally formed square structure

- High tensile strength from 15kN/m to 50kN/m

- Strain at maximum load ≤13%

- Junction effiency ≥93%

- Resistance to installation damages

- Long design service life

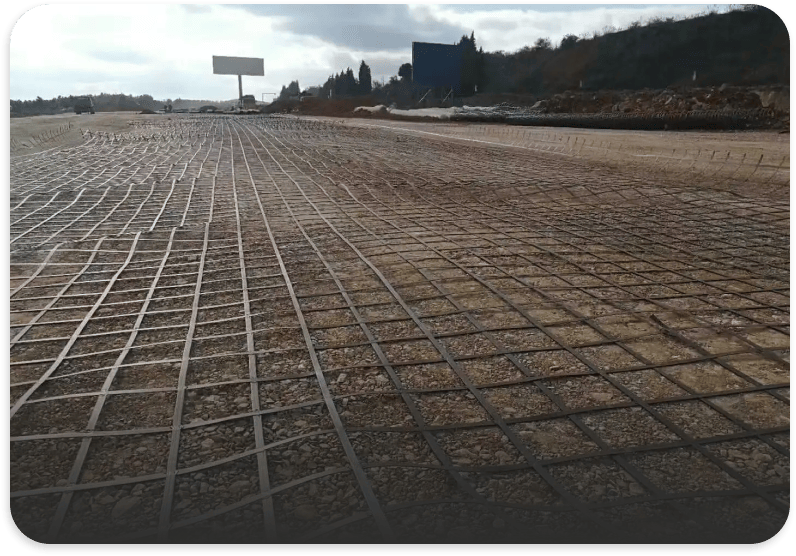

Lianyi polypropylene (PP) extruded biaxial geogrid is a widely used geosynthetic material designed to provide reinforcement in civil engineering projects such as road construction, soil stabilization, and embankment reinforcement. Ensuring the quality and performance of PP extruded biaxial geogrids involves rigorous testing and quality control measures. These measures are essential to verify that the geogrids meet industry standards and perform effectively in their intended applications.

Quality Control Measures

- Raw Material Inspection:

- Standards: Manufacturer’s specifications and industry standards.

- Procedure: The quality of polypropylene resin and other raw materials is inspected upon receipt. Tests include melt flow index, density, and impurity content to ensure consistency and quality.

- Production Monitoring:

- Procedure: Continuous monitoring of the extrusion and stretching processes to ensure that the geogrid meets dimensional and mechanical property requirements. Parameters such as temperature, stretching ratio, and extrusion speed are controlled and recorded.

- In-Process Testing:

- Procedure: Samples are taken from the production line at regular intervals for in-process testing. This includes tensile strength tests, aperture size measurements, and visual inspections to detect any defects or inconsistencies.

- Finished Product Testing:

- Procedure: Comprehensive testing of the final product to ensure it meets all specified standards. This includes tensile strength, elongation, aperture stability, and durability tests.

- Batch Certification:

- Procedure: Each batch of geogrid is certified based on the results of the testing. Documentation includes test results, compliance certificates, and traceability information.

- Storage and Handling:

- Procedure: Proper storage and handling procedures to prevent damage or degradation of the geogrids. This includes protection from UV radiation, chemicals, and mechanical damage.

- Third-Party Audits:

- Procedure: Regular third-party audits to verify compliance with industry standards and quality control procedures. Audits may include site inspections, review of test reports, and verification of manufacturing processes.

Choose Lianyi PP Biaxial Geogid, you will find out,

Polypropylene extruded geogrids offer several advantages for various civil engineering and construction applications:

- High Tensile Strength: Polypropylene geogrids possess high tensile strength, making them suitable for reinforcing soil structures and distributing loads effectively. This helps in enhancing the stability of embankments, retaining walls, and slopes.

- Chemical Resistance: Polypropylene is inherently resistant to many chemicals, including acids and alkalis. This property makes polypropylene geogrids suitable for applications where exposure to chemicals is a concern, such as in waste containment facilities or chemical storage areas.

- Lightweight: Polypropylene geogrids are lightweight, making them easy to handle and install. This characteristic reduces transportation costs and labor requirements during installation.

- High Junction Efficiency: The extrusion manufacturing process of polypropylene geogrids allows for the formation of interlocking nodes and ribs, ensuring high junction efficiency. This results in improved load transfer within the geogrid, enhancing its overall performance.

- Resistance to Biological Degradation: Polypropylene geogrids are resistant to biological degradation, such as from microorganisms and insects. This property extends their service life in various environmental conditions, including humid and organic-rich soils.

- Durability: Polypropylene geogrids exhibit excellent durability and long-term performance due to their resistance to ultraviolet (UV) radiation and environmental factors. This ensures that the geogrids maintain their structural integrity over extended periods, even in harsh outdoor environments.

- Cost-Effectiveness: Polypropylene geogrids offer a cost-effective solution for soil reinforcement and stabilization compared to traditional methods like increasing the thickness of soil layers or using conventional materials like steel. The reduced material and labor costs, along with easier installation, contribute to overall project savings.

- Versatility: Polypropylene geogrids are versatile and can be used in various civil engineering applications, including road construction, embankment reinforcement, slope stabilization, and erosion control. Their adaptability to different soil types and project requirements makes them a preferred choice for engineers and contractors.

Conclusion

Overall, the advantages of polypropylene extruded biaxial geogrids make them a reliable and efficient solution for enhancing the performance and longevity of civil engineering structures while offering cost savings and environmental benefits.