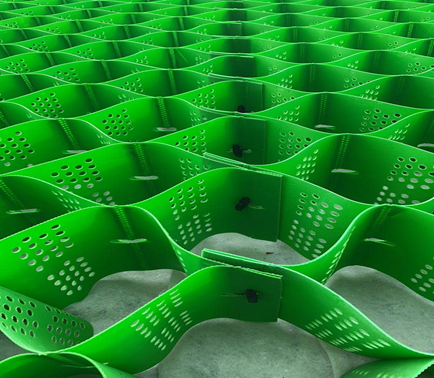

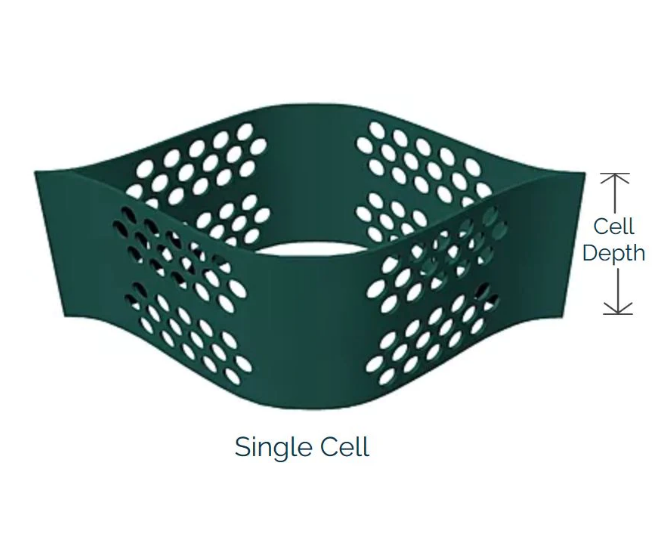

Key Features of HDPE Perforated Geocells:

- Material: Made from high-density polyethylene, which provides high tensile strength, chemical resistance, and durability.

- Perforations: The cells are perforated to allow for water drainage and to prevent hydrostatic pressure buildup.

- Structure: The honeycomb structure provides effective soil confinement, reducing lateral movement and increasing load-bearing capacity.

- Flexibility: The geocells can be expanded and contracted, making them easy to transport and install.

Applications:

- Soil Stabilization: Used to reinforce weak soils, providing stability to the structure and preventing soil erosion.

- Slope Protection: Helps in stabilizing slopes and preventing landslides by confining the soil and preventing it from moving.

- Load Support: Enhances the load-bearing capacity of the soil in areas like parking lots, roads, and railway bases.

- Channel and Shoreline Protection: Used to protect channels and shorelines from erosion caused by water flow.

- Retaining Walls: Used in the construction of retaining walls to provide additional support and stability.

Lianyi provides consistent improvement in HDPE Geocell

Lianyi, a leader in the geosynthetics industry, is renowned for its continuous improvement and innovation in product development and manufacturing processes. Their dedication to quality, performance, and sustainability sets them apart in the market. This guide explores Lianyi’s strategies for consistent improvement and their impact on the geosynthetics industry.

- Process Optimization:

- Continuously optimize the extrusion, perforation, welding, and expansion processes to improve efficiency and product quality.

- Implement lean manufacturing principles to reduce waste and enhance productivity.

- Employee Training:

- Train employees on the latest manufacturing techniques, quality control procedures, and safety protocols.

- Encourage continuous learning and improvement among the workforce.

- Innovation and R&D:

- Invest in research and development to explore new materials, additives, and manufacturing techniques.

- Stay updated with industry trends and advancements to maintain a competitive edge.

- Customer Feedback:

- Gather feedback from customers on the performance and quality of the geocell.

- Use this feedback to make continuous improvements in the product and manufacturing process.

Commitment to Quality

- Quality Management Systems:

- ISO Certification: Lianyi is ISO 9001 certified, ensuring adherence to international standards for quality management.

- Continuous Monitoring: Regular audits and inspections of production processes ensure that products meet stringent quality criteria.

- Advanced Manufacturing Techniques:

- Precision Engineering: Utilization of state-of-the-art machinery and precision engineering techniques to produce high-quality geosynthetics.

- Automation: Integration of automation in manufacturing processes to enhance consistency, efficiency, and product quality.

- Raw Material Selection:

- High-Grade Materials: Sourcing high-grade raw materials to ensure superior product performance and longevity.

- Supplier Partnerships: Building strong relationships with reliable suppliers to maintain a steady supply of quality materials.

Innovation in Product Development

- Research and Development:

- R&D Investment: Significant investment in R&D to explore new materials, technologies, and applications for geosynthetics.

- Innovation Centers: Establishment of innovation centers dedicated to developing cutting-edge solutions and advancing industry standards.

- Product Diversification:

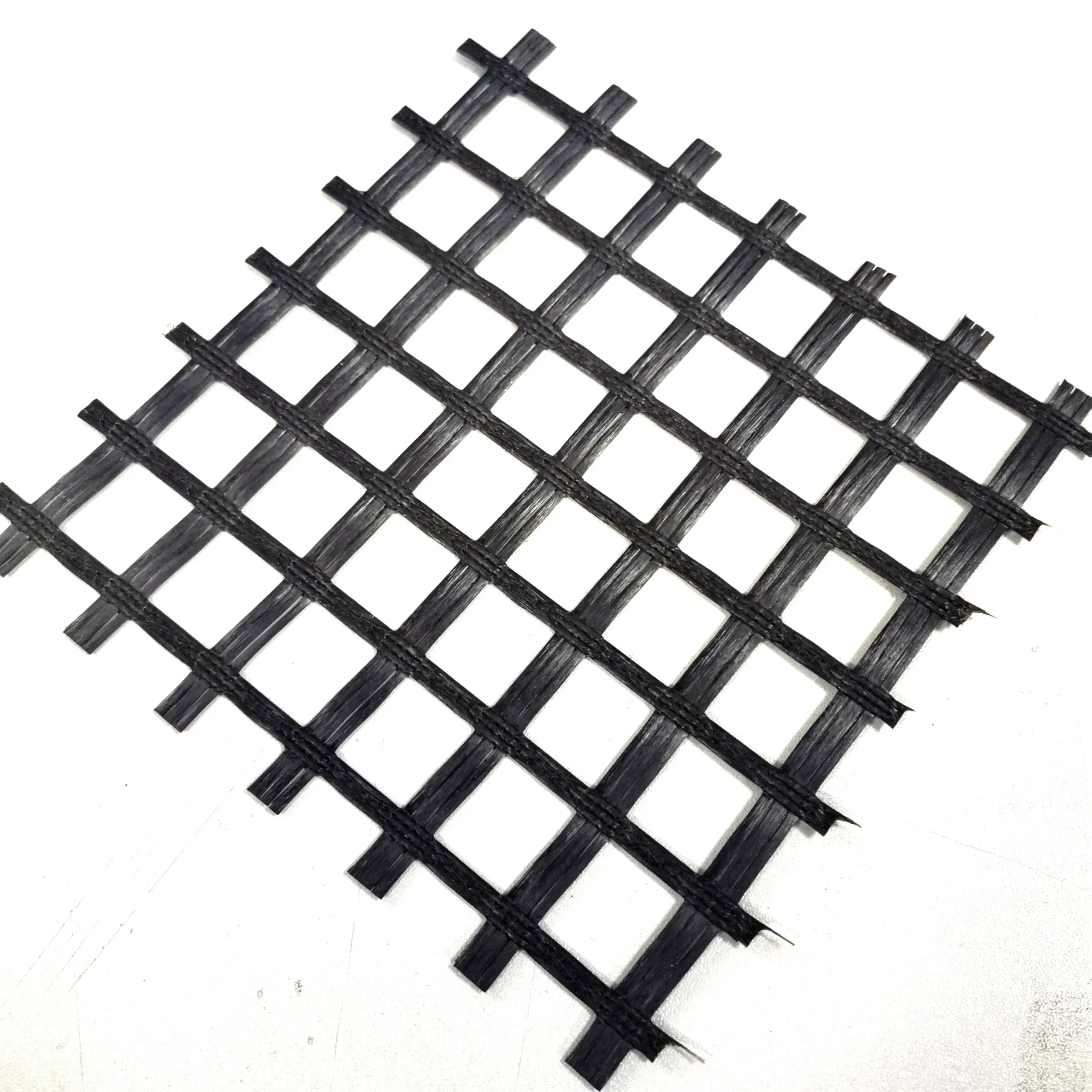

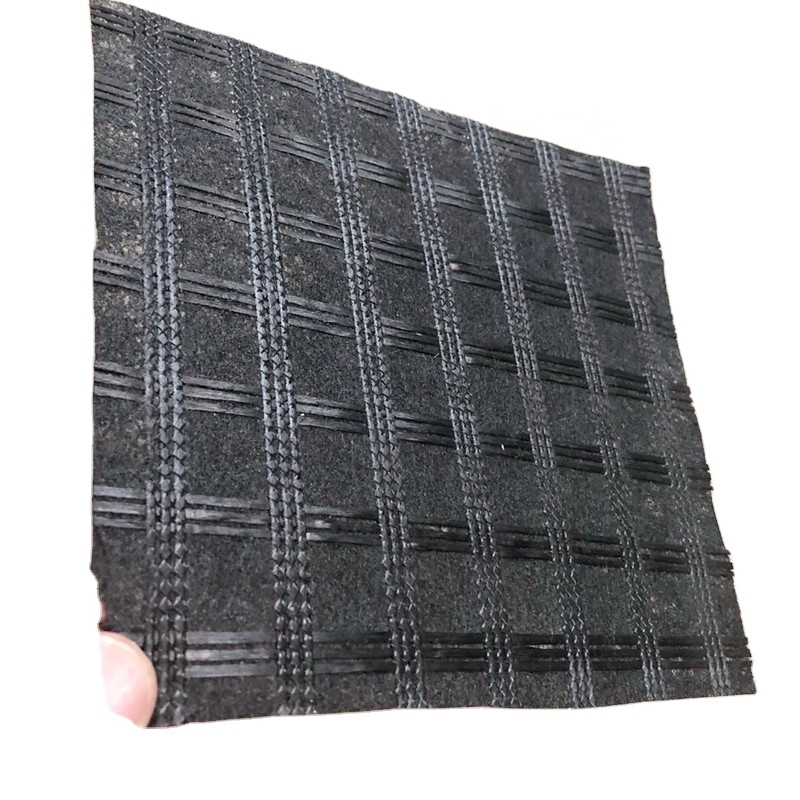

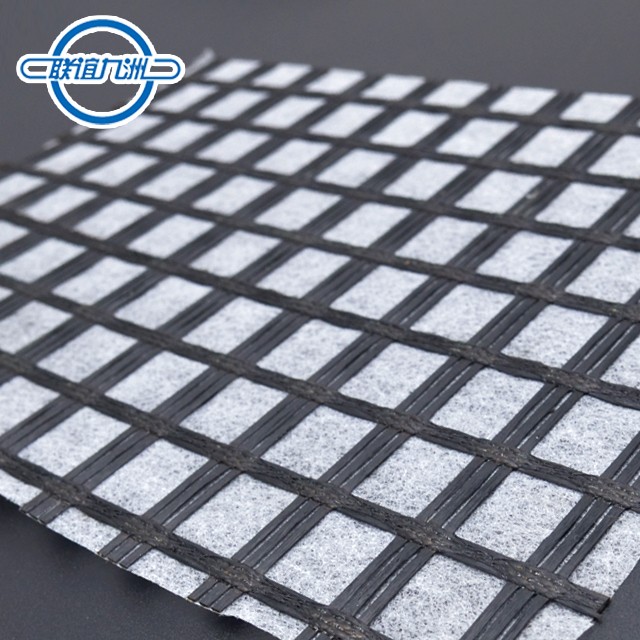

- Wide Range of Products: Offering a diverse portfolio of geosynthetics, including geotextiles, geogrids, geocells, and geomembranes, tailored to various applications.

- Customized Solutions: Providing customized geosynthetic solutions to meet specific project requirements and challenges.

- Sustainable Practices:

- Eco-Friendly Materials: Development of eco-friendly geosynthetics that minimize environmental impact and promote sustainability.

- Recycling Initiatives: Implementation of recycling initiatives to reduce waste and promote the reuse of materials in production.

Customer-Centric Approach

- Customer Feedback:

- Feedback Mechanisms: Establishing robust feedback mechanisms to gather insights from customers on product performance and areas for improvement.

- Responsive Adjustments: Quickly responding to customer feedback by making necessary adjustments to products and services.

- Technical Support:

- Expert Consultation: Providing expert consultation and technical support to help customers select the right geosynthetic solutions for their projects.

- Training Programs: Offering training programs and workshops to educate customers on the proper installation and use of geosynthetics.

- Global Reach:

- International Presence: Expanding global presence with a network of distributors and partners to serve customers worldwide.

- Localized Solutions: Tailoring solutions to meet the unique needs of different regions and markets.

Continuous Improvement Strategies

- Lean Manufacturing:

- Efficiency Optimization: Implementing lean manufacturing principles to optimize production efficiency and reduce waste.

- Process Streamlining: Streamlining processes to improve productivity and minimize defects.

- Performance Monitoring:

- KPIs: Establishing key performance indicators (KPIs) to monitor and measure the effectiveness of manufacturing processes and product quality.

- Data Analytics: Utilizing data analytics to identify trends, address issues, and drive continuous improvement.

- Employee Development:

- Training Programs: Investing in employee training and development to enhance skills and knowledge.

- Innovation Culture: Fostering a culture of innovation and continuous improvement within the organization.

- Collaboration and Partnerships:

- Industry Collaboration: Collaborating with industry partners, research institutions, and universities to stay at the forefront of technological advancements.

- Knowledge Sharing: Participating in industry conferences, seminars, and workshops to share knowledge and learn from peers.