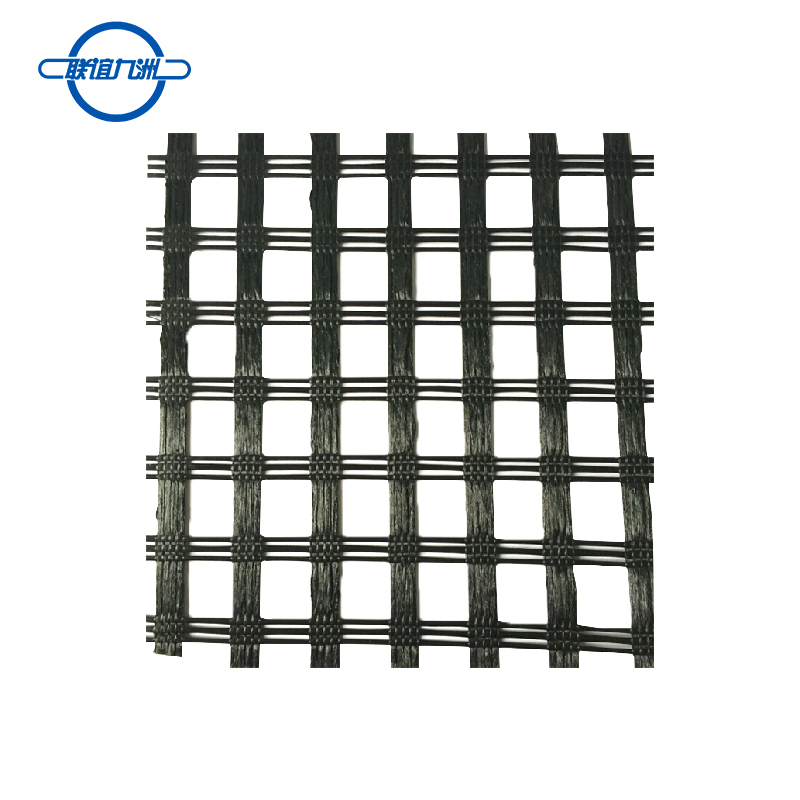

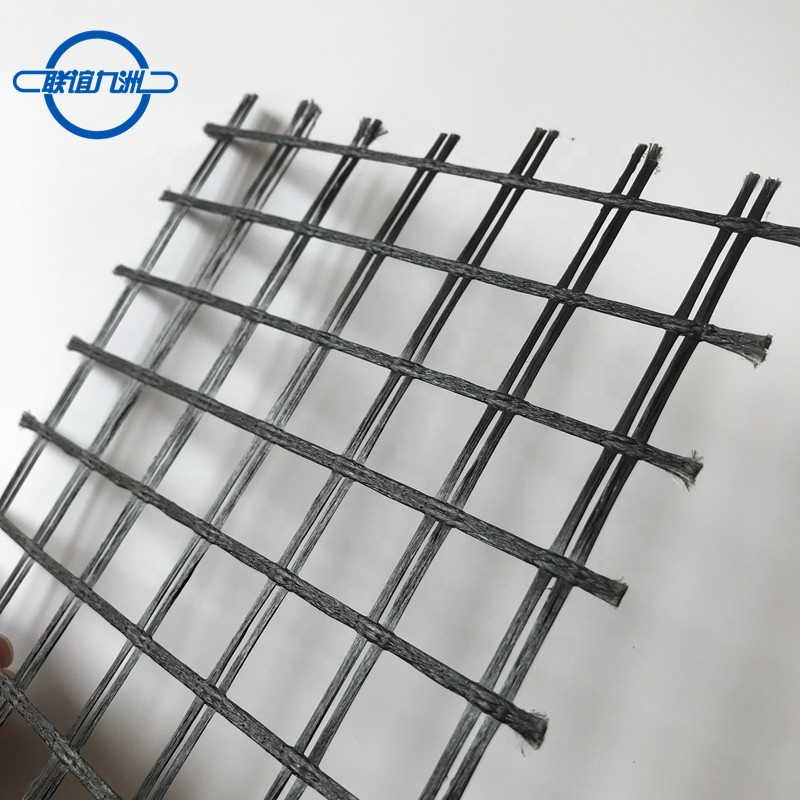

fiberglass geogrid

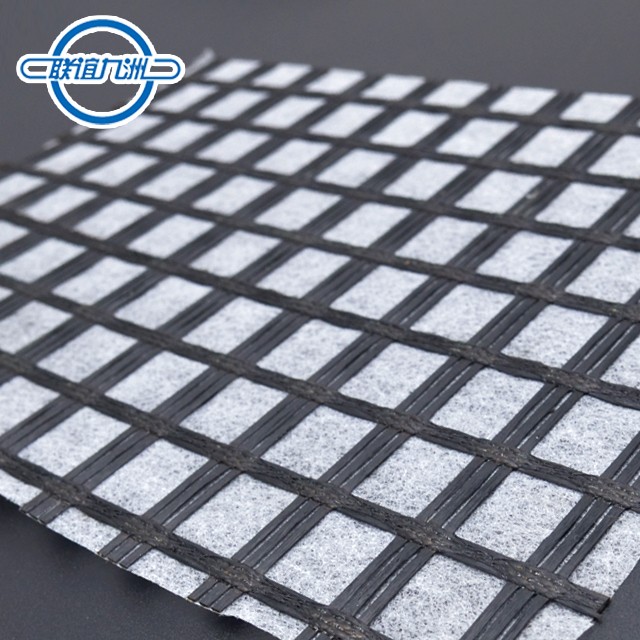

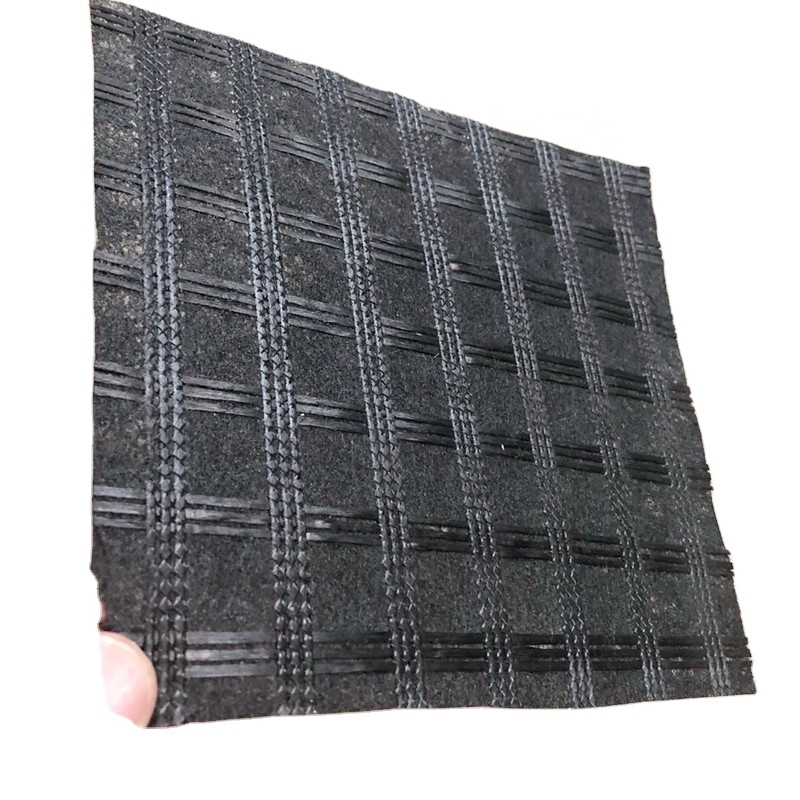

Fiberglass Geogrid Composite:

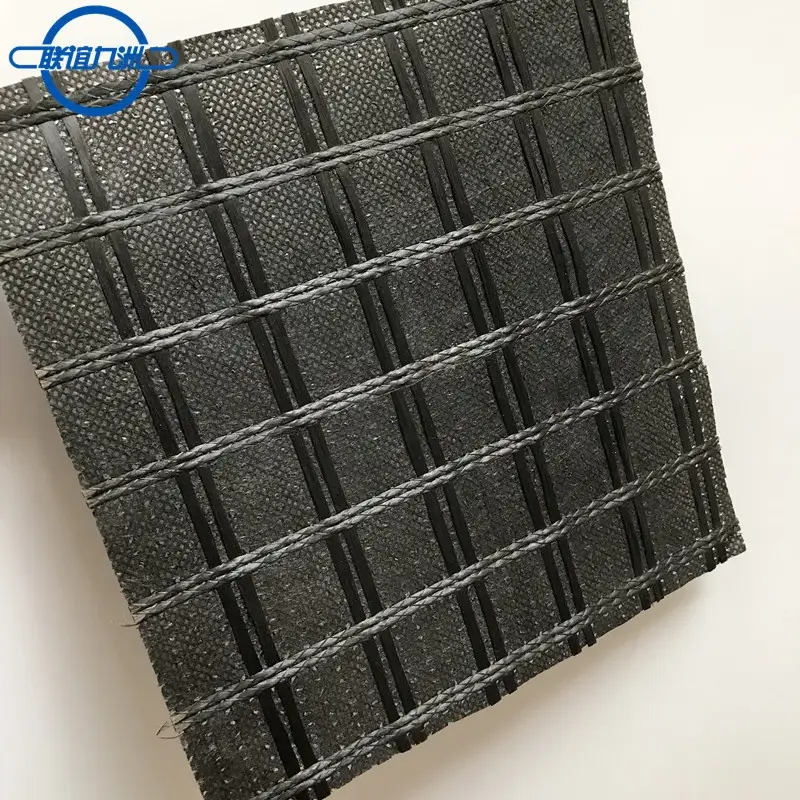

- Enhanced Tensile Strength: The addition of the nonwoven fabric layer can improve the overall tensile strength and durability.

- Moisture Barrier: The nonwoven fabric layer acts as a moisture barrier, preventing water penetration and reducing the risk of pavement damage.

- Improved Stress Absorption: The composite material can better absorb and distribute stress, increasing the lifespan of the reinforced structure.

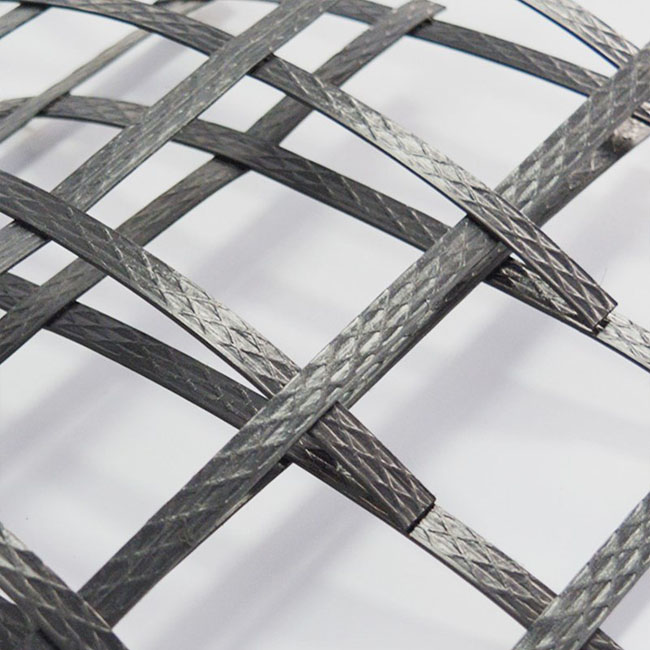

Fiberglass geogrids are high-strength geosynthetic materials made from fiberglass yarns that are coated with a bituminous polymer, to enhance durability and resistance to environmental conditions. These geogrids are primarily used for reinforcement in pavement and road construction, providing excellent tensile strength and durability while being cost-effective.

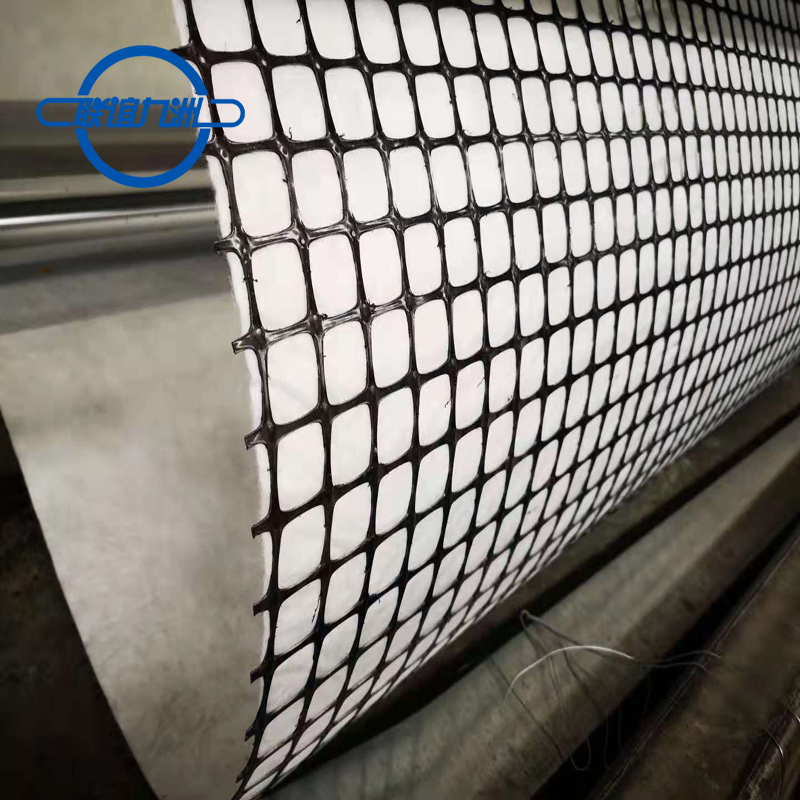

Fiberglass Geogrid knitted with nonwoven fabric is an Aspahlt reinforcement Geocomposite. It is

specifically designed for asphalt reinforcement with an additional moisture proofing benefit. Its composite

characteristic provides a continuous non-deforming water resistant barrier. The geogrid is bitumen coated

which ensures proper adhesion to the asphalt layers over the tack coat surface, and further optimizes the

chemical compatibility between the fiberglass reinforcement and the pavement overlay to create a solid bond

of the asphalt layers over the tack coat surface. This bond ensures that the reinforcing grid is in a position to

effectively accept and distribute tensile stresses.

High strength Fiberglass Geocomposite is a combination of fiberglass geogrid and nonwoven getextile suitable for heavy duty trafficked area construction. This geogrid composite can significantly improve pavement performance and extend service life.