Geogrid

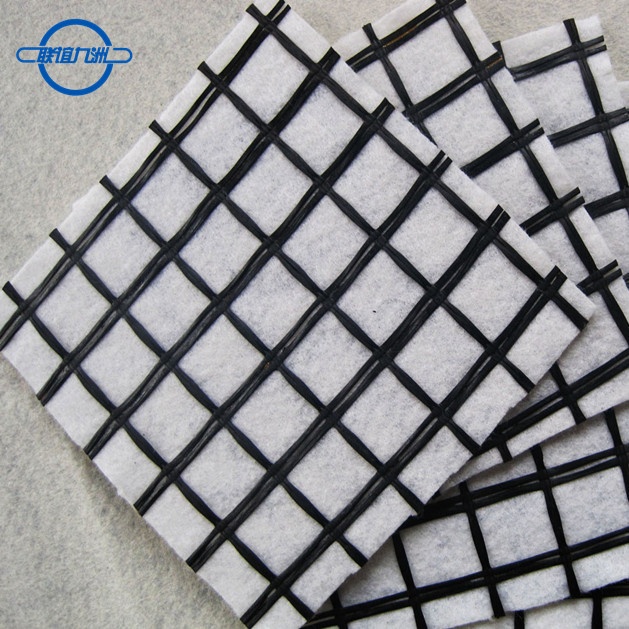

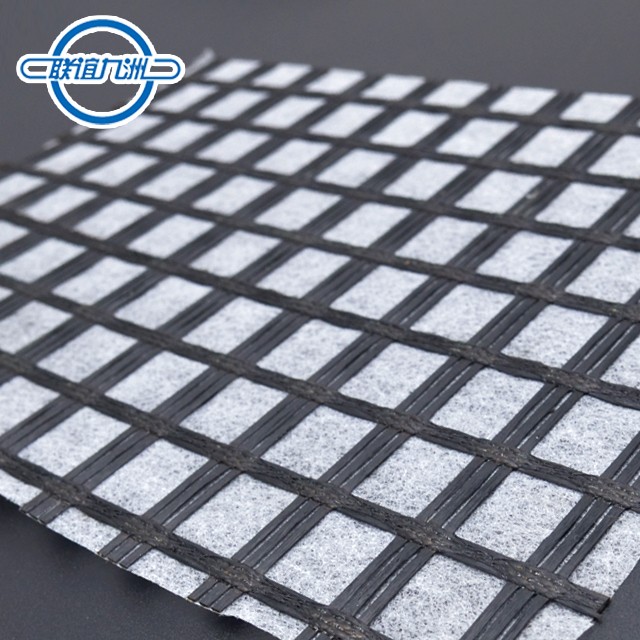

Fiberglass Geogrid Composite:

- Enhanced Tensile Strength: The addition of the nonwoven fabric layer can improve the overall tensile strength and durability.

- Moisture Barrier: The nonwoven fabric layer acts as a moisture barrier, preventing water penetration and reducing the risk of pavement damage.

- Improved Stress Absorption: The composite material can better absorb and distribute stress, increasing the lifespan of the reinforced structure.

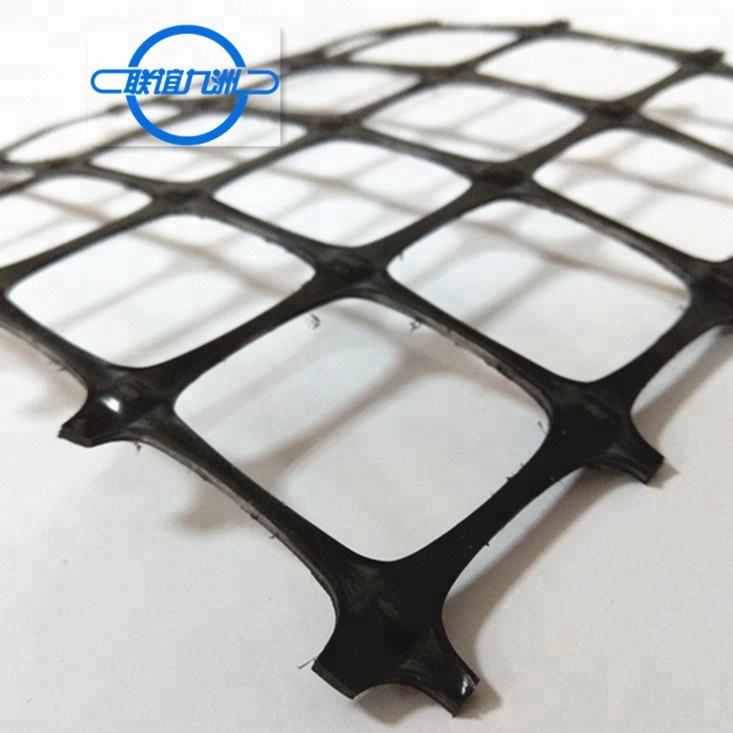

The PP extruded geogrid BX1200 is a biaxial geogrid commonly used for soil stabilization and reinforcement in various civil engineering applications. With a tensile strength of 30 kN/m in the longitudinal direction and 20 kN/m in the transverse direction, it provides effective load distribution and soil reinforcement.

PP biaxial geogrid with big apertures is made from processes including polypropylene resins feeding, extrusion, machine direction and cross machine direction streching and roll collecting. Big aperture size (65mm) is suitable for big gravels (d50 from 4.5mm to 22mm).

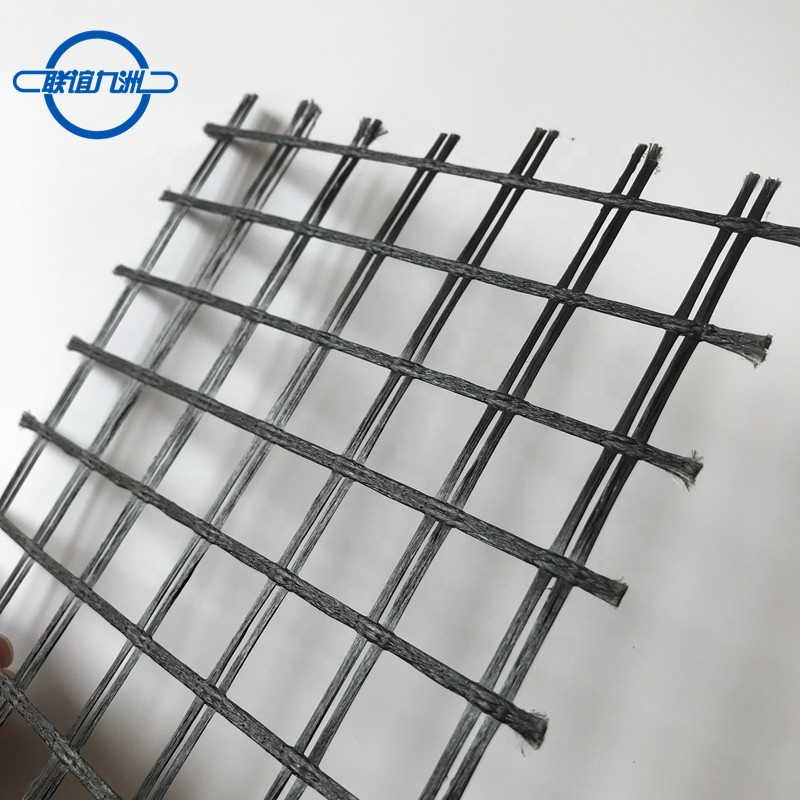

Fiberglass geogrids are high-strength geosynthetic materials made from fiberglass yarns that are coated with a bituminous polymer, to enhance durability and resistance to environmental conditions. These geogrids are primarily used for reinforcement in pavement and road construction, providing excellent tensile strength and durability while being cost-effective.

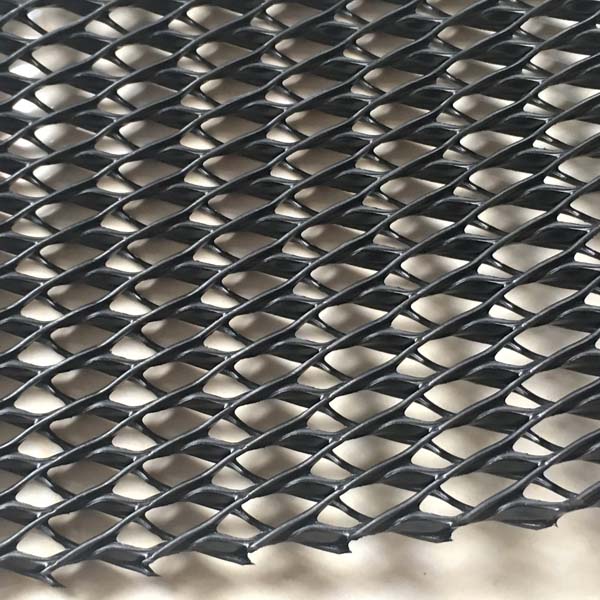

A 2-dimensional geonet, also known as a drainage net, is a type of geosynthetic material designed primarily for drainage applications in civil engineering, construction, and environmental projects. It consists of polymeric ribs arranged in a two-dimensional grid pattern, forming a net-like structure. This configuration allows for effective fluid and gas drainage, making 2D geonets particularly useful in applications such as landfill liners, road and railway construction, retaining walls, and tunnel drainage.

Polypropylene (PP) extruded mesh is widely used in coal mining for ground support, reinforcement, and safety. This type of mesh is made through an extrusion process, producing a grid with uniform apertures and high tensile strength. It is particularly suited for mining applications due to its durability, flexibility, and resistance to harsh environmental conditions.

Polyester geogrids are widely used in the construction of false roofs, particularly in mining applications, to provide ground support and enhance safety. A false roof is typically installed in underground mines to provide immediate support to the roof, reducing the risk of collapse and ensuring the safety of workers.

Lianyi PP Uniaxial Geogrid is especially designed for soil reinforcement. It is manufactured with high quality Polypropylene resins, from the process of extruding and longitudinal stretching. Lianyi PP Uniaxial Geogrid has high tensile strength, excellent interlock capacity and low creep deformation.

PP (Polypropylene) welded geogrid is another type of geosynthetic material used for soil reinforcement, ground stabilization, and various civil engineering applications. Similar to PET welded geogrids, PP welded geogrids are constructed from extruded polypropylene strips that are welded together, often using ultrasonic welding techniques.

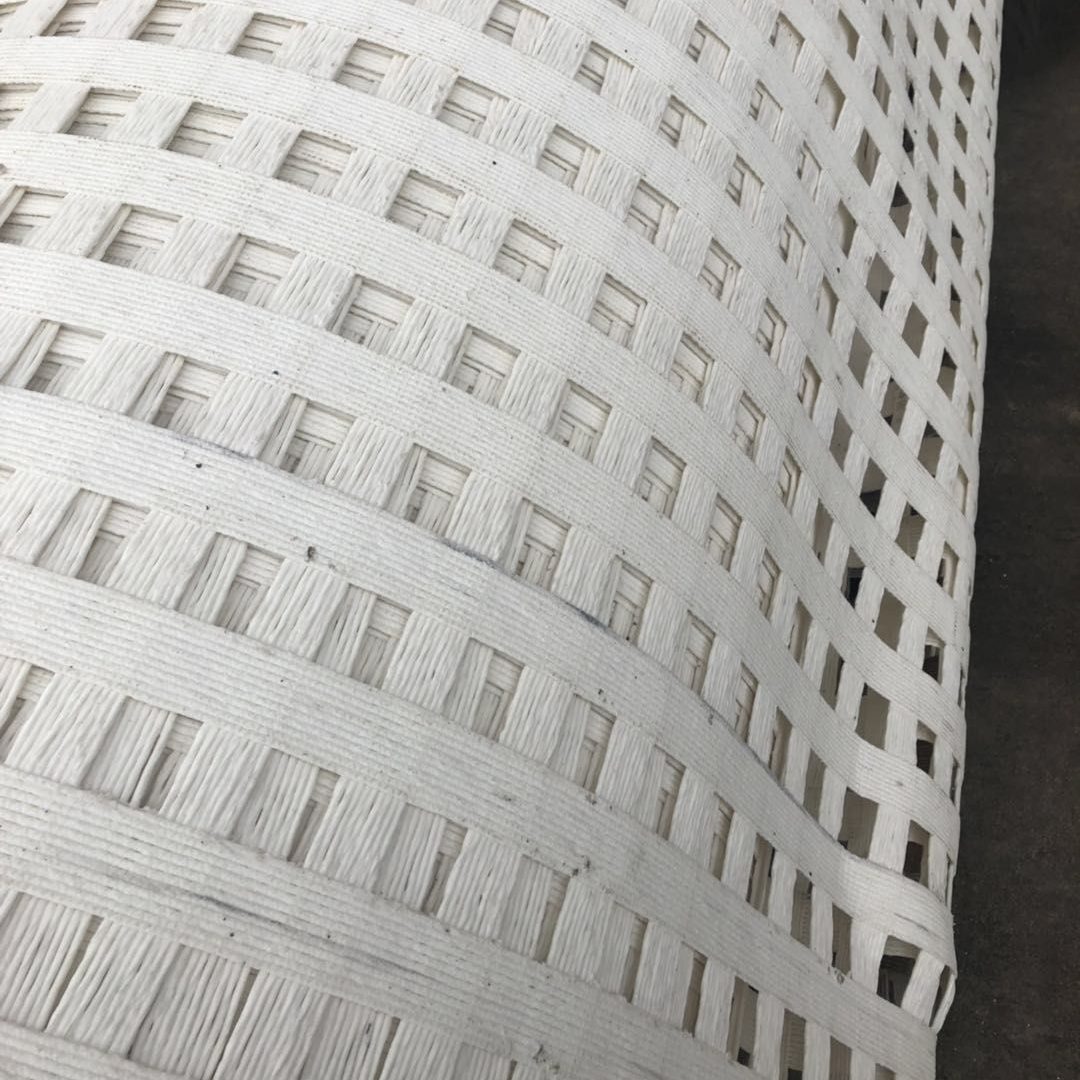

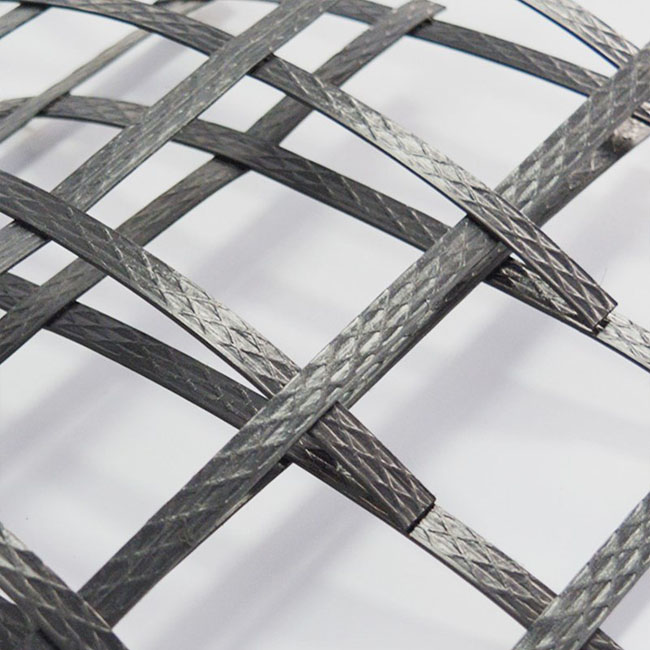

PET welded geogrid is a type of geosynthetic material made from extruded polyethylene terephthalate (PET) strips that are heat-bonded together through an ultrasonic welding process. This construction method provides strong and durable geogrids that are used for soil reinforcement, ground stabilization, and other civil engineering applications.