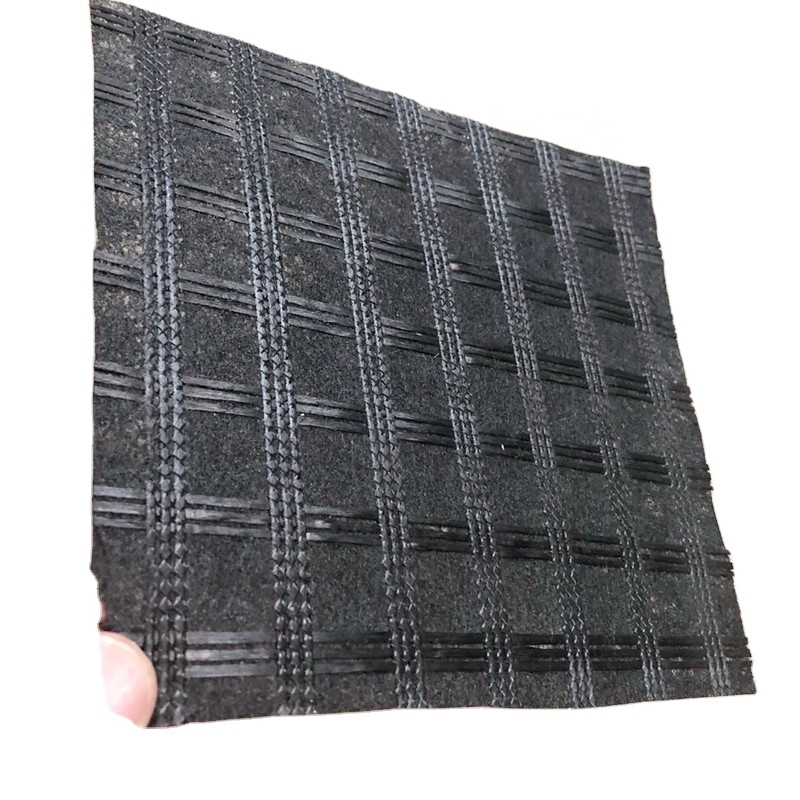

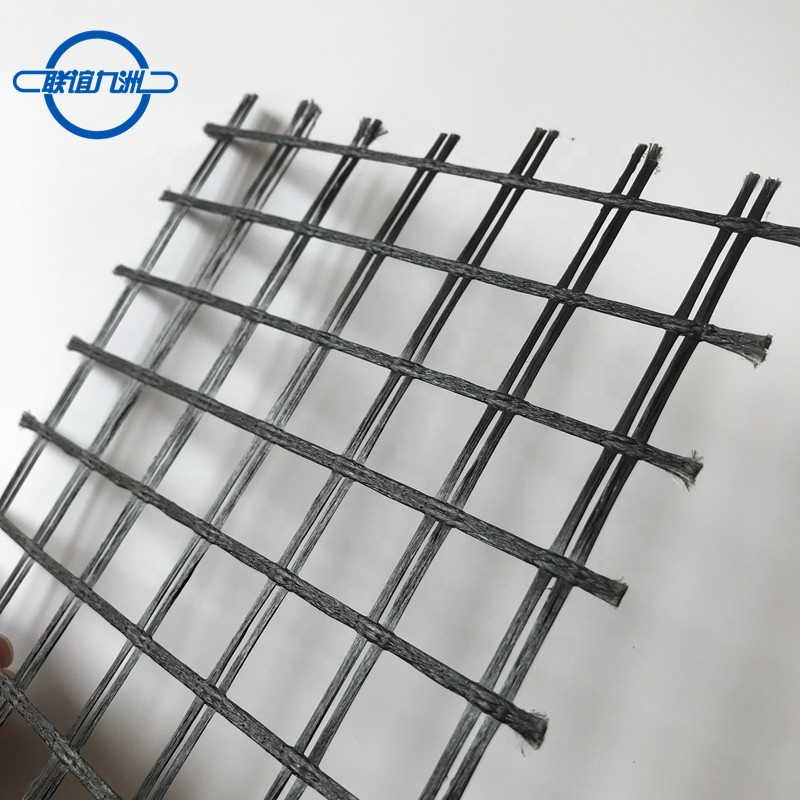

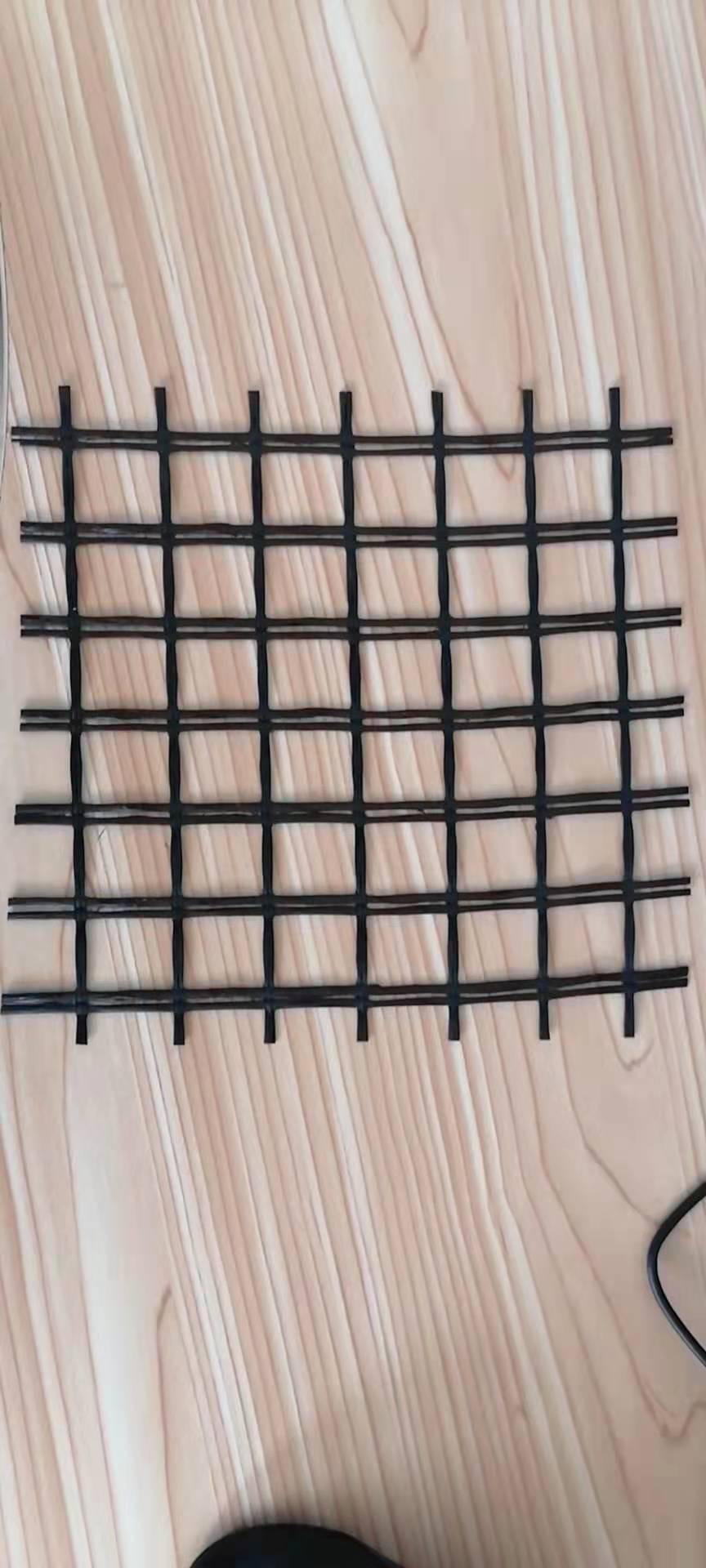

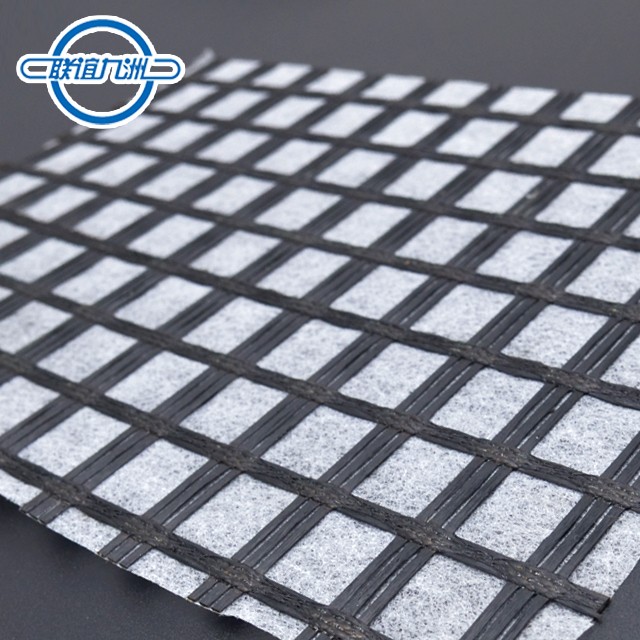

Fiberglass Geogrid

Fiberglass geogrids are particularly beneficial for asphalt reinforcement due to several key properties that enhance the performance and longevity of asphalt pavements. Here are the primary reasons for using fiberglass geogrids in asphalt reinforcement:

Key Benefits of Fiberglass Geogrid for Asphalt Reinforcement:

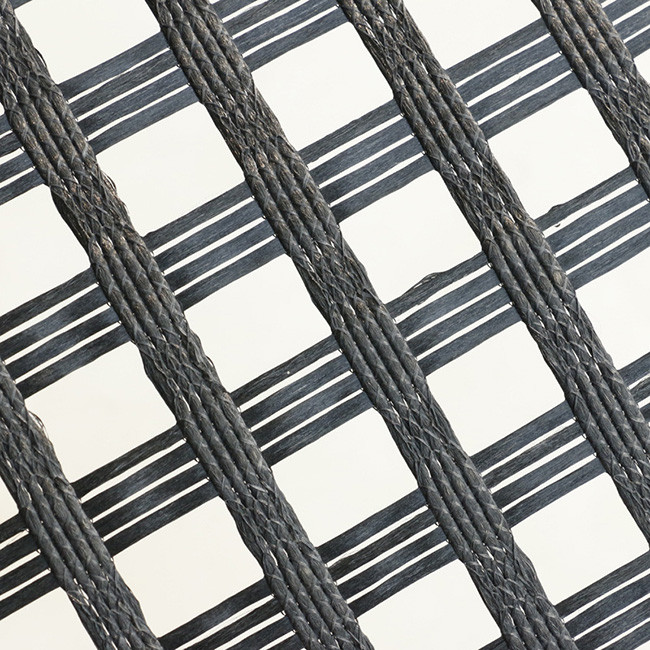

- High Tensile Strength:

- Crack Prevention: Fiberglass geogrids have high tensile strength, which helps distribute loads and stresses more evenly across the pavement. This distribution reduces the occurrence and propagation of cracks, particularly reflective cracking from underlying layers.

- Load Distribution: Enhances the pavement’s ability to withstand traffic loads by improving load distribution, leading to a more durable road surface.

- Low Elongation:

- Minimal Creep: Fiberglass geogrids exhibit low elongation under load, meaning they maintain their structural integrity and reinforcement properties over time without significant deformation.

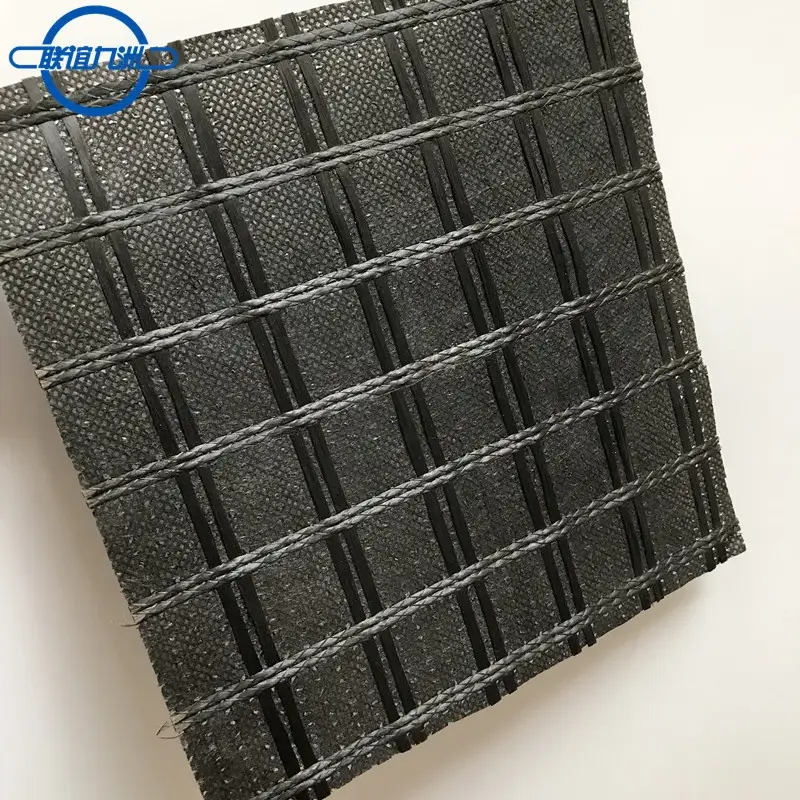

- Stable Reinforcement: Provides consistent and stable reinforcement to the asphalt layer, maintaining the pavement’s structural integrity.

- Durability:

- Chemical Resistance: Resistant to chemicals, including those found in asphalt and the surrounding environment, ensuring long-term performance without degradation.

- Environmental Resistance: Resistant to UV radiation, moisture, and temperature variations, making them suitable for various climates and conditions.

- Improved Pavement Performance:

- Extended Lifespan: By preventing cracks and improving load distribution, fiberglass geogrids extend the lifespan of asphalt pavements, reducing the need for frequent repairs and maintenance.

- Cost-Effective: The extended lifespan and reduced maintenance requirements lead to cost savings over the life of the pavement.

Some benefits you will find out after you installed with Lianyi fiberglass geogrid,

- Extended Pavement Life: By reinforcing pavements, fiberglass geogrid helps in extending the service life of roads, reducing maintenance costs.

- Cost-Effective: It offers a cost-effective solution for infrastructure projects by reducing the need for frequent repairs and maintenance.

- Ease of Installation: The material is lightweight and easy to handle, which simplifies the installation process and reduces labor costs.

- Environmental Benefits: Its resistance to environmental degradation ensures that it remains effective over long periods, reducing the environmental impact of frequent replacements.

Quality control:

- ISO Standards:

- ISO 10319: It specifies the method for determining the tensile properties of geogrids.

- ISO 13431: This standard focuses on the requirements for geogrid for use in the reinforcement of soil and other fill materials.

- EN Standards (European Standards):

- EN 12447: This standard provides guidelines for the long-term durability of geogrids under typical environmental conditions.

- EN 13249: Specifies the characteristics required for geogrids used in the construction of roads and other trafficked areas.

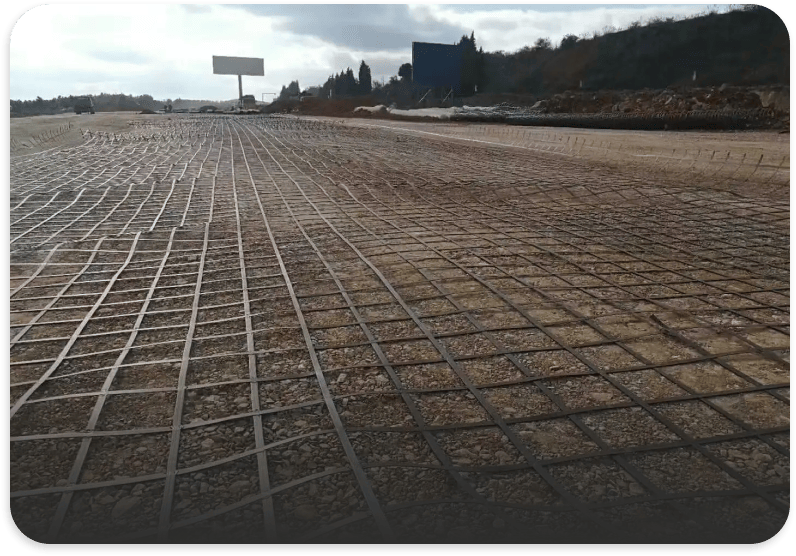

Installation Process

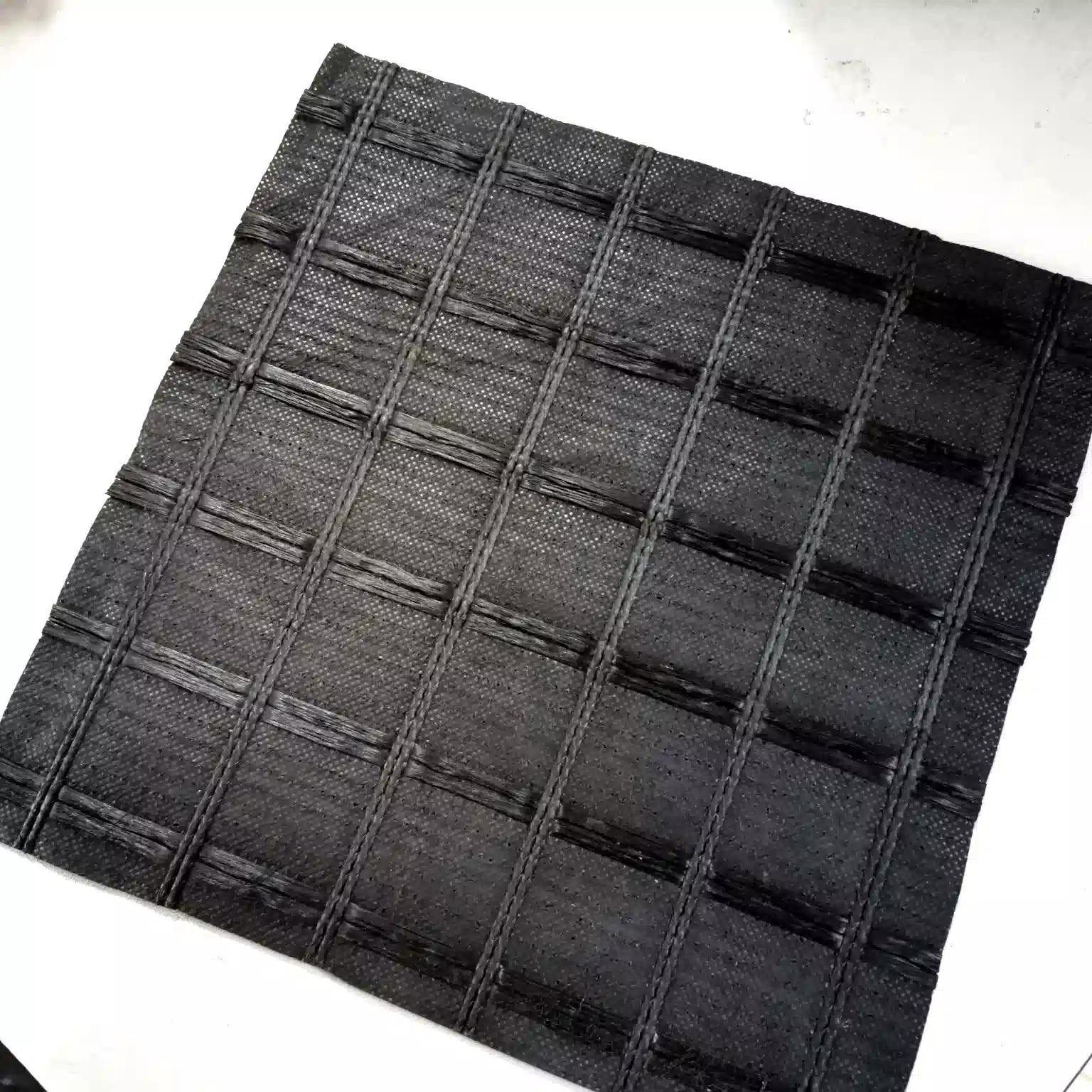

- Site Preparation: The installation process begins with preparing the site, which includes clearing and leveling the ground.

- Laying the Geogrid: The fiberglass geogrid is unrolled and laid out on the prepared surface. Care is taken to ensure that it is stretched properly to eliminate wrinkles and ensure full contact with the ground.

- Fixing the Geogrid: It is then fixed in place using pins or other anchoring methods. Overlapping sections are secured to ensure continuity and strength.

- Covering: Once the geogrid is in place, it is covered with the appropriate construction material, such as asphalt or soil, and compacted to the required specifications.

Case Studies

- Highway Rehabilitation: In many highway rehabilitation projects, fiberglass geogrid has been used to reinforce the pavement layers, resulting in significant improvements in road performance and reduction in maintenance costs.

- Airport Runways: At several airports, the use of fiberglass geogrid in runway construction has led to enhanced durability and resistance to heavy aircraft loads, ensuring safer and more reliable operations.

- Slope Stabilization: In projects involving slope stabilization, the use of fiberglass geogrid has prevented landslides and erosion, maintaining the stability of the terrain even under adverse weather conditions.

Fiberglass geogrid offers numerous benefits that make it an indispensable material in modern construction and civil engineering. From enhancing structural integrity and extending pavement life to offering cost-effective and environmentally friendly solutions, its advantages are comprehensive. Its ease of installation, versatility, and resistance to degradation further contribute to its value in a wide range of applications. As infrastructure demands continue to grow, the use of reliable and durable materials like fiberglass geogrid will remain crucial in ensuring the safety, sustainability, and efficiency of construction projects.